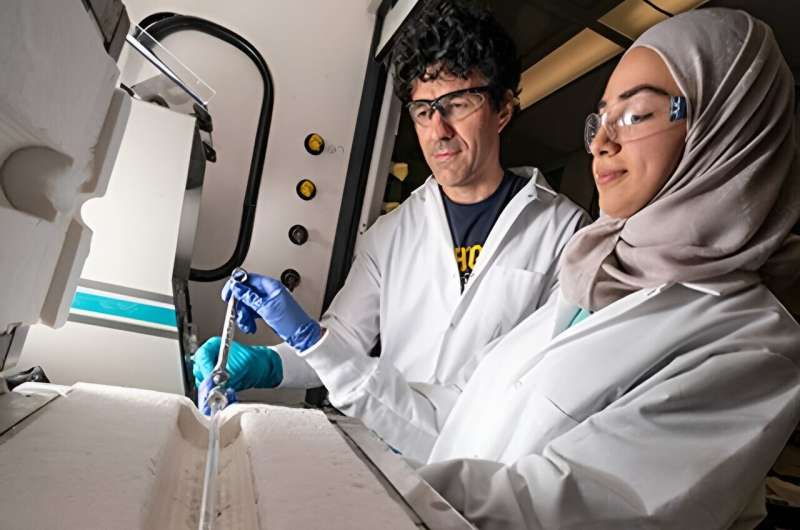

Rawan Almallahi, a doctoral graduate of chemical engineering and the examine’s first writer, is getting ready a reactor for a efficiency take a look at inside a furnace. Suljo Linic, the Martin Lewis Perl Collegiate Professor of Chemical Engineering and the examine’s corresponding writer, assists Almallahi. Credit score: Sandra Swisher, Division of Chemical Engineering

A brand new approach to make an essential ingredient for plastics, adhesives, carpet fibers, family cleaners and extra from pure gasoline might cut back manufacturing prices in a post-petroleum financial system by tens of millions of {dollars}, due to a brand new chemical reactor designed by College of Michigan engineers.

The reactor creates propylene, a workhorse chemical that can be used to make a protracted checklist of commercial chemical compounds, together with elements for nitrile rubber present in automotive hoses and seals in addition to blue protecting gloves. Most propylene used at this time comes from oil refinerieswhich accumulate it as a byproduct of refining crude oil into gasoline.

As oil and gasoline fall out of vogue in favor of natural gasphoto voltaic, and wind energymanufacturing of propylene and different oil-derived merchandise might fall under the present demand with out new methods to make them.

Pure gasoline extracted from shale holds one potential different to propylene sourced from crude oil. It is wealthy in propanewhich resembles propylene carefully sufficient to be a promising precursor materials, however present strategies to make propylene from pure gasoline are nonetheless too inefficient to bridge the hole in provide and demand.

“It’s very hard to economically convert propane into propylene,” stated Suljo Linic, the Martin Lewis Perl Collegiate Professor of Chemical Engineering and the corresponding writer of the examine published in Science.

“You need to heat that reaction to drive it, and standard methods require very high temperatures to produce enough propylene. At those temperatures, you don’t just get propylene but solid carbon deposits and other undesirable products that impair the catalyst. To regenerate the reactor, we need to burn off the solid carbon deposits often, which makes the process inefficient.”

The researchers’ new reactor system effectively makes propylene from shale gasoline by separating propane into propylene and hydrogen gasoline. It additionally provides hydrogen a approach out, altering the stability between the focus of propane and response merchandise in a approach that permits extra propylene to be made. As soon as separated, the hydrogen will also be safely burned away from the propane, heating the reactor sufficient to hurry up the reactions with out making any undesirable compounds.

This separation is achieved by means of the reactor’s nested, hollow-fiber membrane tubing. The innermost tube is made up of supplies that splits the propane into propylene and hydrogen gasoline. Whereas the tubing retains many of the propylene contained in the innermost chamber, the hydrogen gasoline can escape into an outer chamber by means of pores in a membrane layer of the fabric. Inside that chamber, the hydrogen gas is controllably burned by mixing in exact quantities of oxygen.

As a result of the hydrogen will be burned contained in the reactor and may function beneath greater propane pressures, the know-how might permit crops to provide propylene from pure gasoline with out putting in additional heaters. A plant that produces 500,000 metric tons of propylene yearly might save as a lot as $23.5 million over different strategies beginning with shale gasin accordance with the researchers’ estimates. These financial savings come on prime of the operational financial savings from burning hydrogen produced in response, reasonably than different fuels.

Extra data:

Rawan Almallahi et al, Overcoming limitations in propane dehydrogenation by co-designing catalysts/membrane programs, Science (2024). DOI: 10.1126/science.adh3712. www.science.org/doi/10.1126/science.adh3712

Supplied by

University of Michigan

Quotation:

New reactor might save tens of millions when making elements for plastics and rubber from pure gasoline (2024, March 21)

retrieved 25 March 2024

from https://techxplore.com/information/2024-03-reactor-millions-ingredients-plastics-rubber.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.