In a landmark growth for the aviation trade, ZeroAvia is making headway with its pioneering high-temperature hydrogen gasoline cell know-how. The inexperienced tech innovator is creating waves, providing a sustainable various that might considerably cut back industrial aviation emissions. This text supplies an inside look into ZeroAvia’s operations and the technical strides the corporate is making.

The Crucial of Excessive Vitality Density in ZeroAvia Know-how and Aviation

Addressing the carbon footprint of business flights, significantly from bigger plane on long-distance routeshas turn out to be a urgent challenge. ZeroAvia is responding to this want by prioritizing excessive vitality density, which is significant for plane operation. The corporate’s dedication to creating hydrogen electrical and gasoline cell-based powerplants demonstrates its imaginative and prescient for a high-powered, low-emission future.

The Fringe of Excessive-Temperature Gas Cells

The distinctive function of ZeroAvia’s know-how is the turbocharging functionality of its high-temperature hydrogen gasoline cells. Working at greater temperatures distinctively permits the usage of air cooling over water cooling methods, simplifying the design and enhancing the ability effectivity. The power to harness the generated warmth and stress for turbocharging additional distinguishes these cells from extra typical low-temperature variants.

A vital side of the high-temperature hydrogen gasoline cells is their potential to function at elevated temperatures, which, surprisingly, boosts each their effectivity and longevity. It’s because objects at greater temperatures dissipate warmth quicker than these at decrease temperatures, a precept that performs a significant position in aviation by addressing the problem of warmth administration in energy methods. By harnessing this phenomenon, their know-how not solely operates extra effectively but in addition guarantees larger reliability together with longer flight occasions attributable to this simple cooling options in comparison with conventional methods. This innovation is vital to advancing not solely sustainable aviation however may be relevant in trains, vehicles, ships, and automobile applied sciences.

Delving into Gas Cell Mechanics

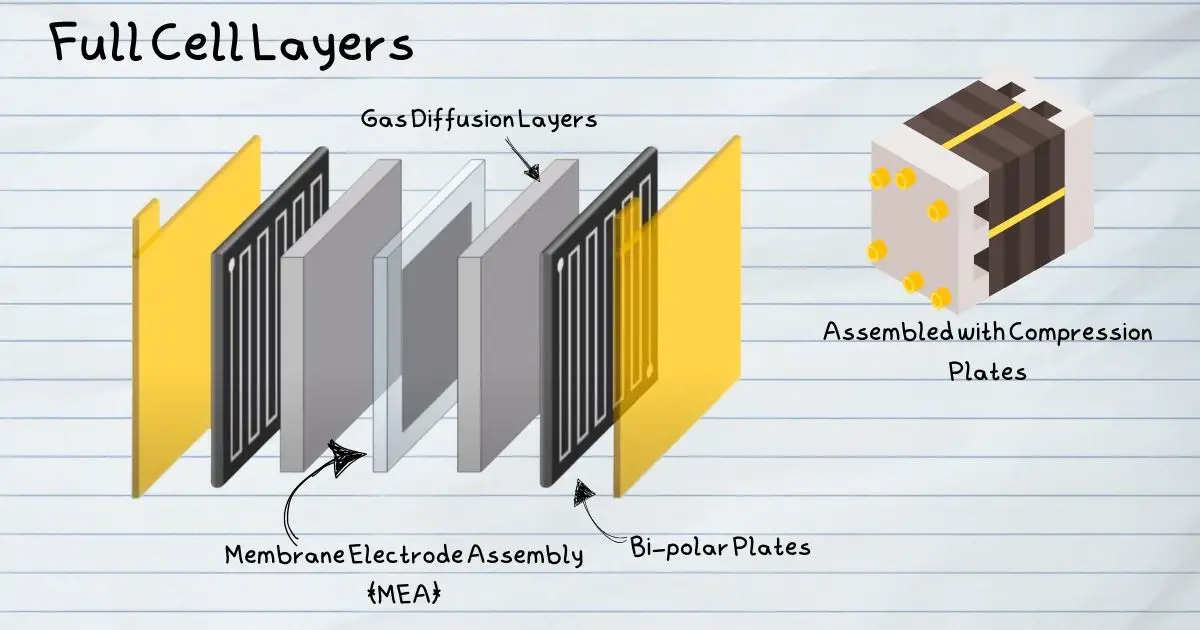

On the coronary heart of ZeroAvia’s system lies the proton trade membrane (PEM) gasoline cell. Its key elements embody bipolar plates, gasoline diffusion layers, and the membrane electrode meeting (MEA). Hydrogen gasoline and oxygen from the air enter the gasoline cell individually. Hydrogen is cut up into protons and electrons, with the protons passing by way of the membrane to the cathode. The electrons are pushed by way of {an electrical} circuit, creating electrical energy. The protons and oxygen mix on the cathode to type water, with warmth being the one byproduct.

Understanding Gas Cell Know-how:

- Proton Trade Membrane (PEM): On the core of the know-how, the PEM facilitates the chemical response that generates electrical energy, performing as a vital pathway for protons.

- Key Parts: The gasoline cell consists of bipolar plates, gasoline diffusion layers, and a membrane electrode meeting (MEA).

- Performance: Hydrogen gasoline enters one facet of the gasoline cell, and oxygen from the air enters the opposite. Upon encountering the catalyst, hydrogen splits into protons and electrons. The protons transfer by way of the PEM to the cathode, whereas electrons journey by way of an exterior circuit, producing electrical energy.

- Output: The response culminates on the cathode, the place protons, electrons, and oxygen from the air mix to supply water and warmth, highlighting the system’s effectivity and environmental friendliness.

Aviation Know-how – Advancing By way of Challenges

Efficiently creating high-temperature gasoline cells that match into light-weight frameworks appropriate for plane has offered ZeroAvia’s specialists with formidable checks. To forestall corrosion, the engineers innovated a protecting layer for the aluminum bipolar plates. Such developments are important in sustaining effectivity and making certain the sturdiness of gasoline cell elements.

Overcoming Challenges in Excessive-Temperature Gas Cells:

- Corrosion Resistance: A notable engineering problem was adapting light-weight aluminum to be used inside the gasoline cells’ corrosive setting, solved by creating a protecting and conductive coating for the bipolar plates.

- Conductivity and Circulate: The design optimally maintains conductivity and permits efficient molecule movement inside the gasoline cell, vital for its operations.

The Foundations of Electrical Technology

Inside these cells, carbon fabric electrodes coated with a platinum catalyst are central to splitting hydrogen for electrical era. ZeroAvia’s enhancements to the catalyst coating have boosted each efficiency and cost-effectiveness, demonstrating the crew’s potential to optimize vital facets of the know-how.

The Position of Catalysts and Electrodes:

- Catalyst Effectivity: The electrodes, constructed from carbon fabric coated with a platinum catalyst, play a pivotal position within the hydrogen splitting course of, with optimized coating growing each efficiency and cost-effectiveness.

- Electrical Technology: This innovation ensures the environment friendly and financial cut up of hydrogen for electrical energy era.

Testing the Boundaries of Energy Output

The robustness and energy of the gasoline cell stack are vetted by way of rigorous testing. ZeroAvia’s engineers meticulously assemble stacks, aiming to scale voltage and energy, with aspirations for the methods to clock 10,000 hours of operational time, reinforcing the longevity of their progressive know-how.

Assembling and Testing the Gas Cell Stack:

- Stack Development: The gasoline cell stack, an meeting of a number of cells, is designed to reinforce voltage and energy output, constructed by layering bipolar plates, MEAs, and gasoline diffusion layers in sequence.

- Efficiency Targets: By way of rigorous testing, ZeroAvia goals for the gasoline cell stack to realize 10,000 hours of operational time, promising outstanding sturdiness and effectivity.

Right here’s Extra About The way it All Works

ZeroAvia Pioneering Past Aviation’s Horizon

While aviation is ZeroAvia’s main stage, the implications of their high-temperature fuel cells extend well into other sectors, producing a ripple effect across various modes of transport that include marine and land. Lightness and efficient thermal management stand out as cornerstones of these applications. Nevertheless, the company recognizes the hurdles that await, particularly in crafting suitable regulatory frameworks and a viable hydrogen infrastructure.

In conclusionZeroAvia is at the forefront of revolutionizing aviation through its cutting-edge hydrogen-electric engines that promise an eco-friendly future with zero-emission flights. By harnessing the power of hydrogen in fuel cells to generate electricity, which in turn powers the aircraft’s propulsors, ZeroAvia turns the vision of clean aviation into impending reality, producing nothing more than water as a byproduct.

This innovative approach not only positions ZeroAvia as a trailblazer in sustainable aviation but also offers passenger and cargo operators, along with aircraft lessors, a golden opportunity to retrofit their fleets for a greener tomorrow. With the ZA600 engine set to cater to 9-19 seat aircraft by 2025 and the ZA2000 engine targeting 40-80 seat aircraft by 2027, ZeroAvia’s roadmap is clear and compelling. Collaboration with Airframe OEMs ensures the integration of engines into both existing and future aircraft designs, further demonstrating the scalability of ZeroAvia’s solutions.

Meanwhile, the company’s efforts to work alongside airports to establish the necessary hydrogen production, storage, and distribution infrastructure underline its commitment to enabling zero-emission routes globally. ZeroAvia not only envisions a clean, sustainable future for aviation but actively paves the way for its realization.

*Main Image Credit: Joe Nicholson-Alaska Airlines