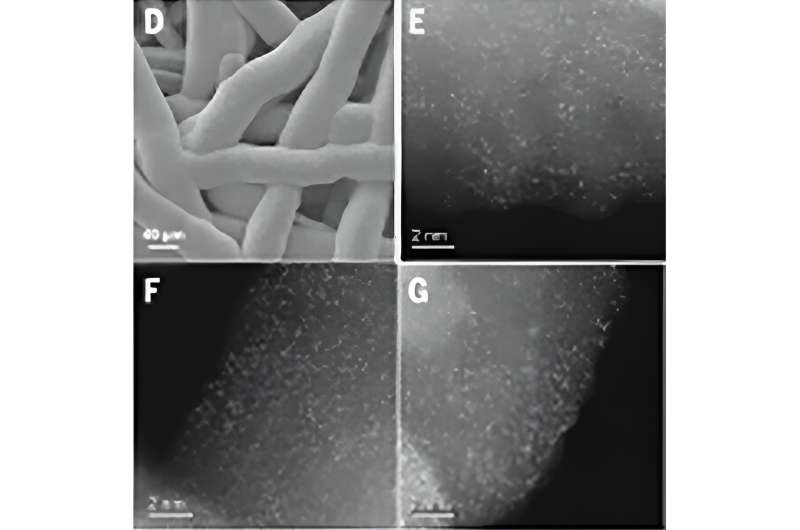

Scanning electon microscope picture of the sunthesized iridium oxide (D) and scanning translission electron microscope pictures of the iridium (shiny spots) dispersed on manganese oxide electrodeposided on a corrosion-resistant platinum-coated titanium mesh (E,F,G). Credit score: RIKEN

Because the world is transitioning from a fossil fuel-based vitality financial system, many are betting on hydrogen to change into the dominant vitality forex. However producing “green” hydrogen with out utilizing fossil fuels just isn’t but attainable on the dimensions we want as a result of it requires iridium, a steel that’s extraordinarily uncommon.

In a research published Could 10 in Scienceresearchers led by Ryuhei Nakamura on the RIKEN Middle for Sustainable Useful resource Science (CSRS) in Japan report a brand new methodology that reduces the quantity of iridium wanted for the response by 95%, with out altering the speed of hydrogen manufacturing. This breakthrough might revolutionize our potential to provide ecologically pleasant hydrogen and assist usher in a carbon-neutral hydrogen financial system.

With 70% of the world lined in water, hydrogen is actually a renewable supply of energy. Nonetheless, extracting hydrogen from water on a scale that may rival fossil fuel-based vitality manufacturing just isn’t but attainable. Present world vitality manufacturing is sort of 18 terawatts, which means that at any given second, about 18 trillion watts of energy is being produced on common worldwide. For different inexperienced strategies of vitality manufacturing to interchange fossil fuelsthey have to be capable to attain the identical charges of vitality manufacturing.

The inexperienced strategy to extract hydrogen from water is an electrochemical response that requires a catalyst. The very best catalysts for this response—those that yield the very best price and probably the most secure hydrogen manufacturing—are uncommon metals, with iridium being the most effective of the most effective. However the shortage of iridium is a giant downside.

“Iridium is so rare that that scaling up global hydrogen production to the terawatt scale is estimated to require 40 years’ worth of iridium,” says co-first creator Shuang Kong.

The Biofunctional Catalyst Analysis Staff at RIKEN CSRS is making an attempt to get across the iridium bottleneck and discover different methods of manufacturing hydrogen at excessive charges for lengthy durations of time. In the long term, they hope to develop new catalysts primarily based on frequent earth metals, which can be extremely sustainable.

In truth, the crew lately succeeded in stabilizing green hydrogen production at a comparatively excessive stage utilizing a type of manganese oxide as a catalyst. Nonetheless, reaching industrial stage manufacturing on this method continues to be years away.

“We need a way to bridge the gap between rare metal- and common metal-based electrolyzers, so that we can make a gradual transition over many years to completely sustainable green hydrogen,” says Nakamura. The present research does simply that by combining manganese with iridium.

The researchers discovered that after they unfold out particular person iridium atoms on a chunk of manganese oxide in order that they did not contact or clump with one another, hydrogen manufacturing in a proton exchange membrane (PEM) electrolyzer was sustained on the identical price as when utilizing iridium alone, however with 95% much less iridium.

With the brand new catalyst, steady hydrogen manufacturing was attainable for over 3,000 hours (about 4 months) at 82% effectivity with out degradation. “The unexpected interaction between manganese oxide and iridium was key to our success,” says co-author Ailong Li. “This is because the iridium resulting from this interaction was in the rare and highly active +6 oxidation state.”

Nakamura believes that the extent of hydrogen manufacturing achieved with the brand new catalyst has excessive potential for instant usefulness. “We expect our catalyst to be easily transferred to real-world applications,” he says, “which will immediately increase the capacity of current PEM electrolyzers.”

The crew has begun collaborating with companions in business, who’ve already been in a position to enhance on the preliminary iridium-manganese catalyst. Transferring ahead, the RIKEN CSRS researchers plan to proceed investigating the precise chemical interplay between iridium and manganese oxide, with hopes of decreasing the quantity of crucial iridium much more.

On the identical time, they are going to proceed collaborating with industrial companions, and plan on deploying and testing the brand new catalyst on an industrial scale within the close to future.

Extra info:

Ailong Li et al, Atomically dispersed hexavalent iridium oxide from MnO2 discount for oxygen evolution catalysis, Science (2024). DOI: 10.1126/science.adg5193. www.science.org/doi/10.1126/science.adg5193

Quotation:

Manganese sprinkled with iridium reduces want for uncommon steel with out altering price of inexperienced hydrogen manufacturing (2024, Could 9)

retrieved 9 Could 2024

from https://techxplore.com/information/2024-05-manganese-sprinkled-iridium-rare-metal.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for info functions solely.