The US Division of Power (DOE) has outlined its analysis and improvement (R&D) priorities to attain the formidable value targets for clear hydrogen set by the Biden administration. Renewable hydrogen manufacturing and storage, in addition to know-how for trucking purposes, are among the many key focus areas recognized by the DOE’s Hydrogen and Gas Cell Applied sciences Workplace in its Multiyear Program Plan.

Sunita Satyapal, director of the mentioned Workplace, acknowledged in a ahead to this system plan:

“While the progress in clean hydrogen today is encouraging, it is also clear that more is needed… and the actions taken must be well-planned, deliberate, carefully executed with measurable outcomes, and they must come without delay.”

DOE’s Clear Hydrogen Roadmap

The Inflation Discount Act, enacted in August 2022, launched tax credit of as much as $3/kg for clear hydrogen producers over the preliminary decade of a undertaking’s lifespan, relying on its carbon emissions lifecycle. This incentivizes clear or green hydrogen manufacturing, positioning it competitively towards gray hydrogen from fossil fuels.

The U.S. leads in inexperienced hydrogen manufacturing as a consequence of these tax credit and a $9.5 billion subsidy from the Infrastructure Funding and Jobs Act. The subsidy contains $8 billion to ascertain no less than 4 regional clean hydrogen hubs.

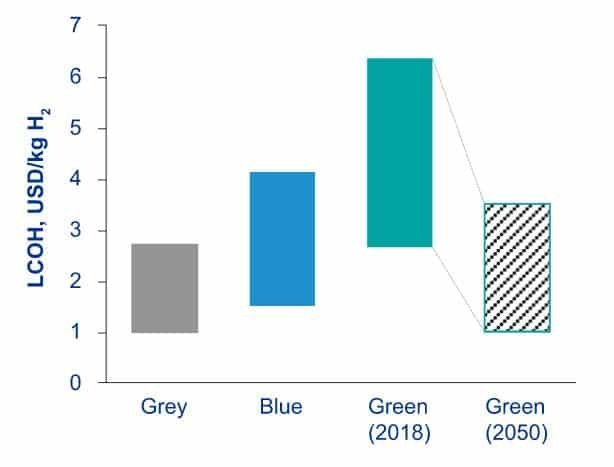

Projections anticipate the price of inexperienced hydrogen to lower considerably by 2050, signaling its long-term viability, and inspiring additional funding.

The DOE goals to considerably cut back the price of zero-emission hydrogen by concentrating on a value of $1/kilogram by 2031. This value contains manufacturing, supply, and dispensation at fueling stations. An interim goal of $2 per kilogram by 2026 has been set.

The company’s plan facilities across the DOE’s “Hydrogen Shot” goal. It additionally seeks to lower the price of electrolyzer methods to $250-500/kW, decrease the price of fuel cell methods for heavy-duty transportation to $80/kW, and obtain a ultimate distributed value of hydrogen gas under $7/kg.

At the moment, hydrogen produced by electrolysis can value no less than $5 per kilogram, or as much as $12 per kilogram when accounting for supply and fueling station prices. Standard hydrogen manufacturing from pure fuel prices about $1.50 per kilogram however comes with a big carbon footprint.

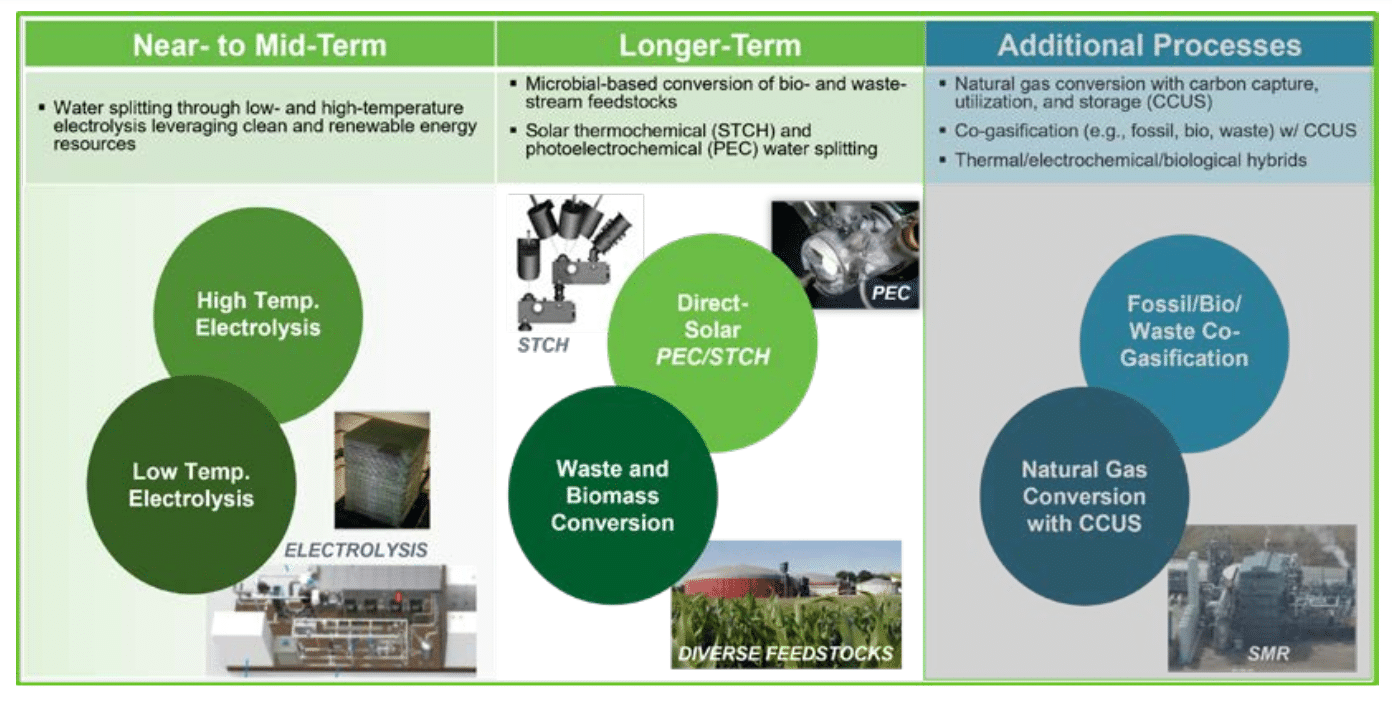

The near-term priorities outlined by the DOE embody bettering electrolyzer know-how to attain decrease systemwide prices and elevated sturdiness. Moreover, analysis and improvement efforts will deal with hydrogen storage and transportation for heavy-duty automobile purposes, aiming to scale back prices and reduce leakage.

DOE Clear Hydrogen Manufacturing Pathways within the RD&D Portfolio

In the long run, the DOE sees alternatives in superior hydrogen manufacturing strategies that require minimal or no electrical energy enter. These embody photo voltaic photoelectrical chemical manufacturing and organic conversion. Supplies-based hydrogen storage, using absorbents or chemical carriers, can also be a spotlight space for long-term analysis and improvement.

Toyota’s Renewable Hydrogen System

Over in California, FuelCell Power and Toyota Motor North America not too long ago celebrated the inauguration of the groundbreaking “Tri-gene” system on the Port of Lengthy Seashore. This modern system makes use of biogas to generate renewable electrical energy, renewable hydrogen, and usable water.

The Tri-gen system was particularly constructed to help the automobile processing and distribution middle for Toyota at Lengthy Seashore. The ability is Toyota’s largest in North America, receiving about 200,000 new Toyota and Lexus automobiles yearly.

The system showcases scalable hydrogen-based know-how that reduces emissions and minimizes reliance on pure sources. Tri-gen’s gas cell know-how converts renewable biogas into electrical energy, hydrogen, and usable water with excessive effectivity and minimal air pollution.

Furthermore, Tri-gen produces as much as 1,200 kg/day of hydrogen to gas Toyota’s incoming light-duty gas cell electrical automobile (FCEV) Mirai. It additionally provides hydrogen to the adjoining heavy-duty hydrogen refueling stationsupporting TLS logistics and drayage operations on the port.

California’s Superior Clear Fleet Regulation mandates zero-emission vehicles for newly registered drayage vehicles. And Tri-gen is well-positioned to help the transition to zero-emission vehicles, together with FCEV Class 8 vehicles. The system’s hydrogen manufacturing might be adjusted primarily based on demand, facilitating the migration to zero-emission automobiles by 2035.

Producing 2.3 megawatts of renewable electrical energy, Tri-gen additionally provides extra electrical energy to the native utility, Southern California Edison. As such, it should contribute to the renewable vitality grid beneath the California Bioenergy Market Adjustment Tariff (BioMAT) program.

Pioneering Modern Carbon Discount Options

General, Tri-gen is anticipated to assist cut back greater than 9,000 tons of CO₂ emissions yearly from the facility grid. It will possibly additionally keep away from over 6 tons of grid nitrogen oxide emissions, whereas doubtlessly lowering diesel consumption by 420,000 gallons/12 months. This aligns with each Toyota’s carbon discount objectives and the Port of Lengthy Seashore’s dedication to modern CO2 discount options.

In abstract, the DOE’s plan underscores the significance of continued innovation and funding in clear hydrogen applied sciences to speed up the transition towards a low-carbon economic system.

The collaboration between FuelCell Power and Toyota is an instance of how modern and sustainable options by hydrogen might help cut back carbon emissions in enterprise operations whereas selling renewable vitality sources.