The manufacturing has began in Jamshedpur, India at a brand new state-of-the-art facility

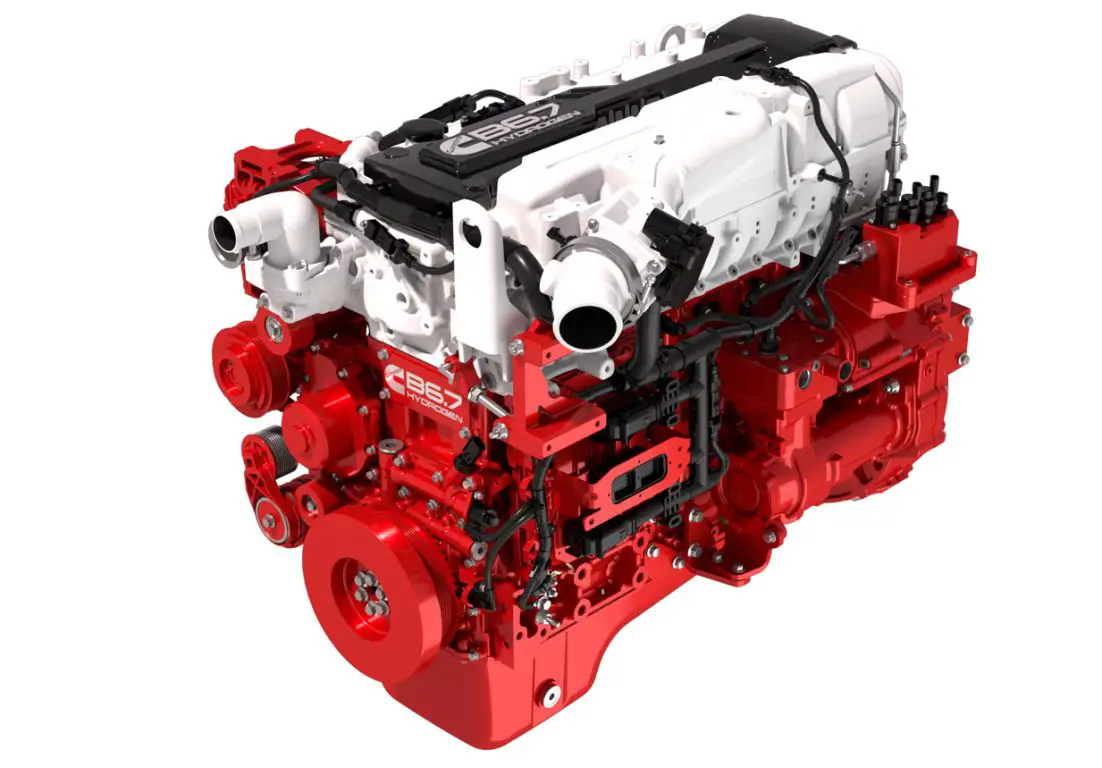

Cummins Inc. just lately introduced that it has began producing hydrogen inside combustion engines (H2-ICE) in a brand new Jamshedpur, India manufacturing facility for Tata Motors.

The primary B6.7H unit was accomplished in March 2024

The hydrogen inside combustion engines persevering with to be produced on the facility are being built-in into Tata Motors trucks. This know-how is being considered as a promising zero- or low-carbon different to diesel energy due to its highly effective efficiency and substantial working vary.

Cummins’ B6.7H engines have notable similarities to present pure fuel and diesel engines, notably by way of the elements they include. Furthermore, they will slot in customary engine automobiles and require related refueling occasions.

By putting in the Cummins B6.7H into its automobiles, it signifies that Tata Motors is taking over a viable, sustainable resolution to help India’s decarbonization technique for business automobiles.

Producing hydrogen inside combustion engines in India

The step to supply the items on the new state-of-the-art manufacturing facility in Jamshedpur is just the newest in a broader partnership between Cummins and Tata Motors in India. The power itself is a three way partnership between the 2 firms, cut up 50/50.

The aim is the manufacturing of the hydrogen inside combustion engines for use in both medium- and heavy-duty commercial vehicles. That mentioned, they will even be producing low-to-zero emissions tech corresponding to H2 gasoline cells and batteries. They view the transfer as an illustration of the dedication each firms have made for powering a extra sustainable and cleaner transport market in India and its export markets.

Transferring sustainable know-how ahead

“Cummins has always believed in bringing the right technology that powers the success of our customers at the right time,” mentioned Cummins Group in India’s Managing Director Ashwath Ram when talking on the Jamshedpur facility’s official opening. “We strive to bring advanced low to zero-emissions technology to the market in pursuit of decarbonising the on-highway industry. Alongside our global expertise and technological capabilities, working with similarly innovative companies like Tata Motors will ensure we realise this ambition.”

Leaders from Cummins Group in India and Tata Motors Restricted on the TCPL GES inauguration ceremony – Picture Supply: Cummins

“Tata Motors’ established legacy of nation-building, innovations, and industry firsts gains further momentum with the opening of this new-age manufacturing facility,” added Tata Motors Government Director Girish Wagh. “The hydrogen-based powertrain aggregates and systems produced here will shape the future of mobility in India, making it smarter and greener. We remain committed to partner our customers to build a better tomorrow by enabling them to progressively adopt emission free and commercially viable solutions for cargo and people mobility.”

Established relationship

Cummins and Tata Motors have been collaborating on numerous tasks and partnerships by way of their Tata Cummins Personal Restricted (TCPL) three way partnership for 3 a long time. A subsidiary of TCPL, known as TCPL GES was created final yr in March as a way to work on the design and improvement of low-and zero-emission propulsion know-how options for India’s business automobiles.

How do hydrogen internal combustion engines work?

Though fuel cells powering electric motors have been making the most headlines until now, there is a way to use H2 to cleanly power vehicles far more similarly to technology already being used on the roads.

In this sense, H2 is burned in the same way that gasoline is burned in a conventional internal combustion engine (ICE). That said, among the advantages of choosing H2 over gasoline or diesel fuel is that it does not result in soot or volatile organic compound emissions.

Are they zero-emission?

Most experts wouldn’t call hydrogen internal combustion engines zero-carbon emission. That said, they are extremely close. The design being used by Cummins and Tata Motors produces similar power and range to diesel but with a reduction in carbon emissions of about 99 percent. For this reason, it is often referred to as zero-carbon technology, even if it technically does still produce a tiny amount of CO2.

Most experts wouldn’t call hydrogen internal combustion engines zero-carbon emission. That said, they are extremely close. The design being used by Cummins and Tata Motors produces similar power and range to diesel but with a reduction in carbon emissions of about 99 percent. For this reason, it is often referred to as zero-carbon technology, even if it technically does still produce a tiny amount of CO2.