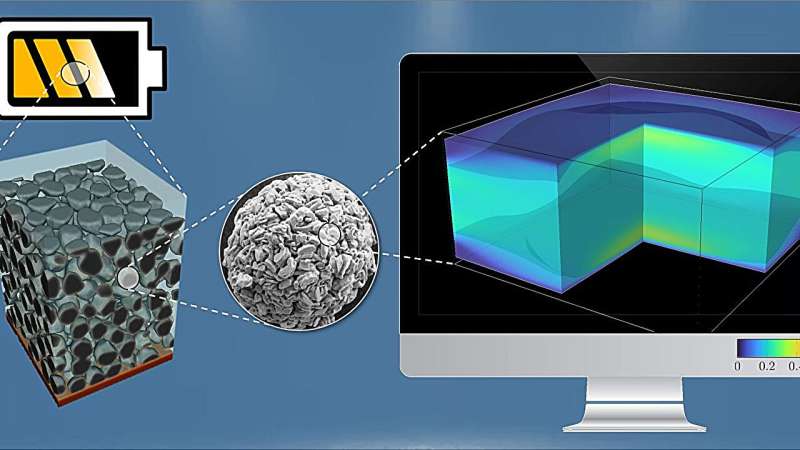

Part of a cathode layer (about 100 micrometers, left) consisting of spherical particles (of about 10 micrometers in diameter, middle) and simulation (proper) of the sodium fraction in a sodium-nickel-manganese oxide crystal. Credit score: Simon Daubner, KIT

Which components decide how shortly a battery might be charged? This and different questions are studied by researchers of Karlsruhe Institute of Expertise (KIT) with the assistance of computer-based simulations.

Microstructural fashions assist to find and examine new electrode supplies. When sodium-nickel-manganese oxide is used as cathode material in sodium-ion batteriessimulations reveal modifications of the crystal construction throughout charging. These modifications result in an elastic deformation, on account of which capability decreases.

The study is printed in npj Computational Supplies.

Analysis into new battery supplies is geared toward optimizing their efficiency and lifelong and at lowering prices. Work can also be underway to cut back the consumption of uncommon components, comparable to lithium and cobalt, in addition to poisonous constituents.

Sodium-ion batteries are thought of very promising on this respect. They’re primarily based on rules just like these of lithium-ion batterieshowever might be produced from uncooked supplies which might be extensively accessible in Europe. And they’re appropriate for each stationary and cell functions.

“Layered oxides, such as sodium-nickel-manganese oxides, are highly promising cathode materials,” says Dr. Simon Daubner, Group Chief on the Institute for Utilized Supplies–Microstructure Modeling and Simulation (IAM-MMS) of KIT and corresponding creator of the research. Throughout the POLiS (stands for Submit Lithium Storage) Cluster of Excellence, he investigates sodium-ion expertise.

Quick charging creates mechanical stress

Nonetheless, cathode supplies of this sort have an issue: Sodium-nickel-manganese oxides change their crystal construction relying on how a lot sodium is saved. If the fabric is charged slowly, all the things proceeds in a well-ordered manner.

“Sodium leaves the material layer by layer, just like cars leaving a carpark story by story,” Daubner explains. “But when charging is quick, sodium is extracted from all sides.” This leads to mechanical stress which will harm the fabric completely.

Researchers from the Institute of Nanotechnology (INT) and IAM-MMS of KIT, along with scientists from Ulm College and the Middle for Photo voltaic Power and Hydrogen Analysis Baden-Württemberg (ZSW), just lately carried out simulations to make clear the scenario.

Experiments verify simulation outcomes

“Computer models can describe various length scales, from the arrangement of atoms in electrode materials to their microstructure to the cell as the functional unit of any battery,” Daubner says. To review the NaXIn1/3Mn2/3O2 layered oxide, microstructured fashions have been mixed with gradual cost and discharge experiments.

The fabric was discovered to exhibit a number of degradation mechanisms inflicting a lack of capability. For that reason, it’s not but suited to industrial functions.

A change within the crystal structure leads to an elastic deformation. The crystal shrinks, which can trigger cracking and capability discount. INT and IAM-MMS simulations present that this mechanical affect decisively determines the time wanted for charging the fabric. Experimental research at ZSW verify these outcomes.

The findings of the research might be transferred partly to different layered oxides. “Now, we understand basic processes and can work on the development of battery materials that are long-lasting and can be charged as quickly as possible,” Daubner summarizes. This might result in the widespread use of sodium-ion batteries in 5 to 10 years’ time.

Extra data:

Simon Daubner et al, Mixed research of section transitions within the P2-type NaXIn1/3Mn2/3O2 cathode materials: experimental, ab-initio and multiphase-field outcomes, npj Computational Supplies (2024). DOI: 10.1038/s41524-024-01258-x

Offered by

Karlsruhe Institute of Technology

Quotation:

Researchers use microstructural modeling to optimize electrode supplies for batteries (2024, Could 21)

retrieved 21 Could 2024

from https://techxplore.com/information/2024-05-microstructural-optimize-electrode-materials-batteries.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.