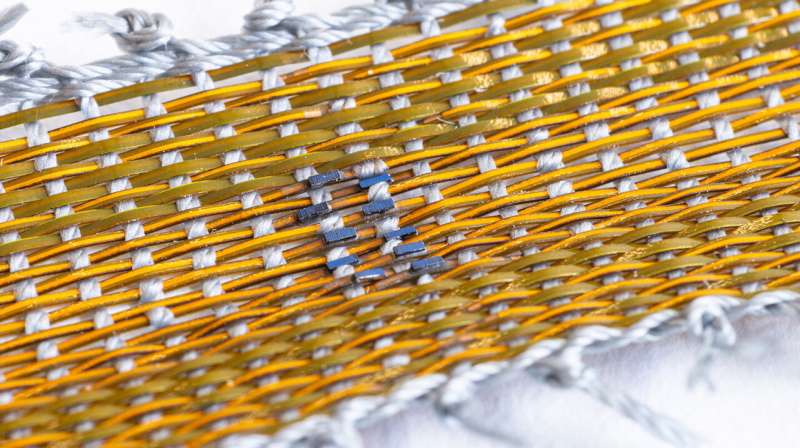

Researchers reduce and assembled tiny photo voltaic cells on skinny, versatile circuit boards earlier than sealing them in a protecting polymer to create a fiber-like strand that was woven with nylon right into a small textile. Credit score: Johns Hopkins APL/Ed Whitman

Researchers from the Johns Hopkins Utilized Physics Laboratory (APL) in Laurel, Maryland, have established new, scalable strategies of growing battery- and solar-powered fibers, making it theoretically attainable for electrical vitality to be harvested from, and saved in, the clothes folks put on.

These fibers may energy high-performance wearable electronics that breathe, stretch and wash identical to typical textiles.

This improvement in fiber energy sources—submillimeter-thin battery and photovoltaic strands that could possibly be woven straight into materials—opens up a brand new world of wearable electronics and sensible textiles.

As a substitute of carrying a coronary heart monitor with cumbersome batteries, a affected person may put on a shirt that has battery- and solar-powered fibers knit into it. Fiber-powered clothes could possibly be heated to maintain an individual heat in chilly environments, or laced with battery- and solar-powered fibers to offer troopers with hands-free audio and video recording within the subject.

“As demands for electronic textiles change, there is a need for smaller power sources that are reusable, durable and stretchable,” mentioned Konstantinos Gerasopoulos, assistant program supervisor for physics, digital supplies and gadgets at APL and lead investigator of this mission.

“Our vision is to develop solar harvesting fibers that can convert sunlight to electricity and battery fibers that can store the generated electricity in the textile.”

Stretching the boundaries

Manufacturing and design have restricted the scalability and efficiency of fiber batteries. Industrial textile gear has been used to fabricate fiber batteries, however its huge scale limits its use to specialised amenities that aren’t appropriate with the battery trade. Customary fiber batteries additionally endure from decrease efficiency as a result of the electrodes are generally twisted collectively, which renders many of the electrode floor inactive.

Now, in a study printed in Superior Supplies Applied sciencesAPL scientists have demonstrated a novel technique to scale up fiber battery fabrication.

Moderately than utilizing textile gear, the APL staff personalized battery gear to attain the thinness required for fiber batteries. This technique, together with the creation of personalized roll-to-roll setups, made the method moveable and appropriate for large-scale manufacturing. All of the gear wanted to create the fiber batteries may slot in a small room.

“We were always designing with roll-to-roll compatibility in mind,” mentioned Rachel Altmaier, the paper’s lead writer. “We need to be able to run all of our processes continuously or else what we develop isn’t relevant. This process could be dropped into an existing manufacturing line.”

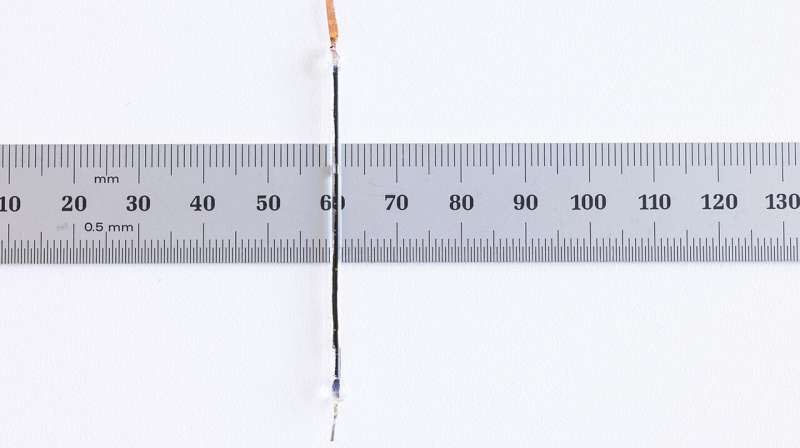

The batteries are manufactured from flat strips of anode and cathode electrodes and a polymer separator which are fed collectively right into a heated roll press and laminated right into a stacked design. The development is much like that of typical pouch cells—suppose cellular phone batteries—and supplies stronger energy and efficiency than customary fiber batteries. The stack is then laser-cut right into a fiber-like strand roughly 700 micrometers broad—concerning the width of 5 human hairs.

This marks the primary use of laser chopping on a full battery stack and demonstrates the strategy’s viability for customizing battery dimension and sustaining efficiency. The chopping system’s quickness additionally makes it scalable.

APL researchers personalized battery gear to attain the thinness required for fiber batteries. The fiber-like battery strand is roughly 700 micrometers broad—concerning the width of 5 human hairs. Credit score: Johns Hopkins APL/Ed Whitman

“We can process 100 meters of total fiber in a little over five hours,” mentioned Jason Tiffany, an engineer at APL and co-author on the paper. “With our process, we can make the fibers smaller and more energy dense, which could open even more opportunities for textile applications.”

The fiber battery work provides to the staff’s know-how toolbox, which has included the event of a versatile lithium-ion battery that may function underneath excessive situations, in addition to secure, fast-charging batteries.

In a second paper additionally printed in Superior Purposeful Suppliesthe APL staff additionally addressed the problem of creating scalable, high-performing fibers that may harvest gentle and convert it into electrical energy.

“Just like with the battery fibers, we were inspired by conventional solar cell technology that is very efficient and robust,” mentioned Gerasopoulos. “We asked, how can we turn these power sources into fibers?”

“The biggest challenge with current solar cell technology is its rigidity,” mentioned Michael Jin, lead writer of the photo voltaic cell paper. “You can imagine shrinking solar panels, like those on a rooftop, into a tiny solar fiber is very challenging.”

To beat this problem, the staff leveraged a selected sort of photo voltaic cell that has each constructive and detrimental terminals on the again facet in a finger-like sample. Ranging from this cell, the researchers reduce and assembled tiny photo voltaic cells on skinny, versatile circuit boards earlier than sealing them in a protecting polymer to create a fiber-like strand. The photo voltaic cells are so small they might match between the ridges of a fingerprint.

“We used standard microelectronics fabrication processes to develop a novel approach that has transformed current rigid solar cell technology into flexible and durable fibers,” Jin mentioned. “Even after bending the fiber 8,000 times, we saw no change in its performance.”

To additional take a look at the robustness of those fibers, the staff constantly uncovered them to gentle within the lab, simulating the overall daylight hours that Washington Dulles Worldwide Airport experiences in a typical spring month. Nonetheless, the fiber effectivity remained unchanged.

In a proof of idea, the researchers used a custom-built mini loom to weave nylon and photo voltaic cell fibers right into a small textile. The swatch of fibers was positioned underneath a lamp and hooked up to a small circuit board and an LED blinker, and inside seconds, the strip powered the blinker’s flashing purple gentle.

The strategy used to assemble and encapsulate the photo voltaic cells onto fiber substrates can also be extensible to different sources. As a substitute of photo voltaic cells, it could possibly be sensors, LEDs or batteries mounted onto the floor of versatile fibers, which may generate quite a few functionalities.

“Our team continues to look for ways to create the most effective, resilient, cutting-edge power sources,” mentioned Jeff Maranchi, analysis program space supervisor in APL’s Analysis and Exploratory Improvement Division.

“Textiles that integrate light energy harvesting and battery fibers could revolutionize what wearables today can achieve. Very soon, these fibers will enable distributed fabric-based power, heating, communications and sensing while providing the comfort and ease of regular textiles.”

Extra data:

Rachel A. Altmaier et al, Excessive‐Linear‐Vitality Layered Fiber Batteries Utilizing Roll‐to‐Roll Lamination and Laser Slicing, Superior Supplies Applied sciences (2024). DOI: 10.1002/admt.202400417

Michael H.‐C. Jin et al, Scalable Crystalline Silicon Photovoltaic Fibers for Digital Textile Functions, Superior Purposeful Supplies (2024). DOI: 10.1002/adfm.202402350

Supplied by

Johns Hopkins University

Quotation:

Breakthrough course of creates subsequent era of powered wearable fibers (2024, Could 23)

retrieved 23 Could 2024

from https://techxplore.com/information/2024-05-breakthrough-generation-powered-wearable-fibers.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.