C-Seize, the UK-based pioneer in carbon seize options, has initiated testing on a novel know-how to cut back carbon emissions from cement manufacturing. That is undoubtedly an thrilling growth for the cement business marking their ongoing efforts to mitigate its environmental influence and contribute to international decarbonization.

Notably, as a part of the XLR8 CCS venture, C-Captureand Wooden, a top-tier engineering agency within the UK, have designed and put in a brand new Carbon Seize solvent compatibility unit (CCSCU). XLR8 CCS venture completely targets the “hard to abate” industries. Presently, it’s working on the Heidelberg Supplies cement plant at Ketton, Lincolnshire, UK.

Unleashing C-Seize’s Subsequent-Gen Carbon Seize Expertise for Cement

C-Seize mentions concrete because the second most used materials on Earth after water. Three tonnes of concrete are used yearly per individual worldwide. Cement, constructed from clinker and gypsum is the primary element of all building works.

Tom White, CEO of C-Seize mentioned:

“Decarbonising industry is one of the most pressing global issues. C-Capture’s XLR8 CCS project is a critical step in the race to net zero as we work with our innovative technology and leading industry partners to demonstrate that an affordable carbon capture solution is a reality – even for industries that are difficult to decarbonize.”

-

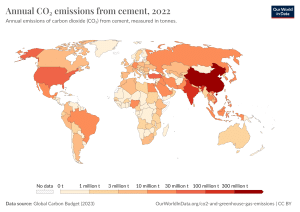

The cement business produces 4 Gt of cement yearly, producing 1.5-2.2 Gt of CO2 emissions, about 5% of the worldwide complete.

It must decarbonize as a result of: Clinker manufacturing makes use of coal or pure gas-fired kilns to warmth limestone (CaCO3), emitting giant volumes of CO2 to type lime (CaO).

The World Enterprise Council for Sustainable Growth estimates that by 2050, the cement business should scale back CO2 emissions by 0.5 Gt yearly to maintain international warming inside 2 °C above pre-industrial ranges.

Subsequently, C-Seize’s hallmark CC know-how, now being examined will successfully take away CO2 from the flue fuel emissions produced throughout cement manufacturing. This unit will illustrate the effectiveness and sturdiness of the know-how in sensible situations.

(*Flue gases are the gases launched to the environment from exhaust pipes of heavy industries.)

Modern Chemistry for a Greener Resolution

C-Seize’s know-how makes use of a essentially totally different chemistry, not like different commercially obtainable carbon seize strategies. It doesn’t depend on amines and is nitrogen-free. This know-how provides a lower-cost and environment-friendly resolutionthe finish product could be renewable gasoline like biomethane. Moreover, it’s extraordinarily sturdy and able to withstanding the difficult flue gases produced by the heavy sectors.

XLR8 CCS Challenge: A Multi-Trade Initiative

The XLR8 CCS venture is showcasing the compatibility of C-Seize’s carbon seize know-how throughout three difficult-to-decarbonize industries: power from waste (EfW), cement, and glass. The venture would conduct six carbon seize trials inside these sectors.

Vast Deployment Throughout Trade Companions

CCSCUs are being deployed at websites owned by venture companions together with Heidelberg Supplies, Power Works Hull, Glass Futures, and Pilkington UK (a part of NSG Group). The success of this venture will place C-Seize and its companions to deploy commercial-scale carbon seize amenities throughout these industries by 2030, probably capturing tens of millions of tonnes of CO2 per yr.

Main Funding Injection Supercharges C-Seize’s Carbon Seize Challenge

The UK Division of Power Safety and Internet Zero awarded a £1.7 million grant to XLR8 CCS from its £1 billion Internet Zero Innovation Portfolio. Personal sector contributions introduced the entire funding to £2.7 million.

This funding comes from the £20 million Carbon Seize, Utilization and Storage (CCUS) Innovation 2.0 program, which goals to speed up the deployment of next-generation CCUS know-how within the UK.

Simon Willis, CEO, of Heidelberg Supplies UK has emphasised deeply the urgency to decarbonize the hardest sectors. He famous,

“Carbon capture is a critical part of our strategy to decarbonize cement production and essential if we are to reach net zero and help our customers achieve their own decarbonization goals.”

He additionally envisions creating new applied sciences and partnerships, exemplifying C-Seize’s dedication. The Heidelberg group will roll out this know-how at different websites if the primary run turns into profitable.

Roadmap to 2030: Methods for Curbing Cement Emissions

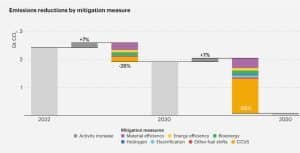

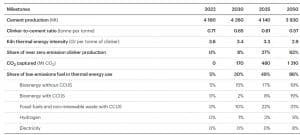

Lowering CO2 emissions whereas assembly cement demand can be difficult. Since 2015, the emissions from cement manufacturing surged to ~ 10%, primarily because of the excessive clinker-to-cement ratio inside China. Due to this fact, curbing emissions roughly by 20% by 2030 will considerably rely on:

- Adopting CCUS applied sciences

- Utilizing environment-friendly uncooked supplies

- Enhancing power and materials effectivity

- Utilizing low-emissions fuels

supply: IEA

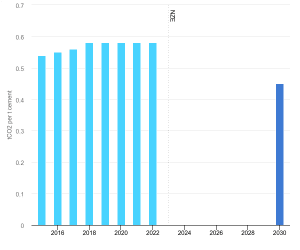

Direct emissions depth of cement manufacturing within the Internet Zero State of affairs, 2015-2030

Sources: IEA calculations, together with inputs from GCCA Statistics and different sources.

Sources: IEA calculations, together with inputs from GCCA Statistics and different sources.

Like C-Seize, many industries are additionally revolutionizing their cement manufacturing strategies. It distinctly exhibits a gradual decline in CO2 emissions from the cement business within the coming years (2030), thus enhancing the web zero transition.