Researchers from Japan and Poland have developed a reactor design that effectively captures CO2 emissions and converts them into usable methane gasoline. This breakthrough might considerably cut back greenhouse gasoline emissions, paving the best way for a carbon-neutral future. Credit score: Professor Mikihiro Nomura SIT, Japan

Lowering carbon emissions from small-scale combustion techniques, reminiscent of boilers and different industrial gear, is a key step in direction of constructing a extra sustainable, carbon-neutral future. Boilers are broadly used throughout numerous industries for important processes like heating, steam technology, and energy manufacturing, making them vital contributors to greenhouse gasoline emissions.

Boilers are usually fairly environment friendly. In consequence, it’s troublesome to cut back CO2 emissions just by enhancing the combustion effectivity. Due to this fact, researchers are exploring various approaches to mitigating the environmental affect of CO2 emissions from boilers. One promising technique to this finish is to seize the CO2 emitted from these techniques and convert it right into a helpful product, reminiscent of methane.

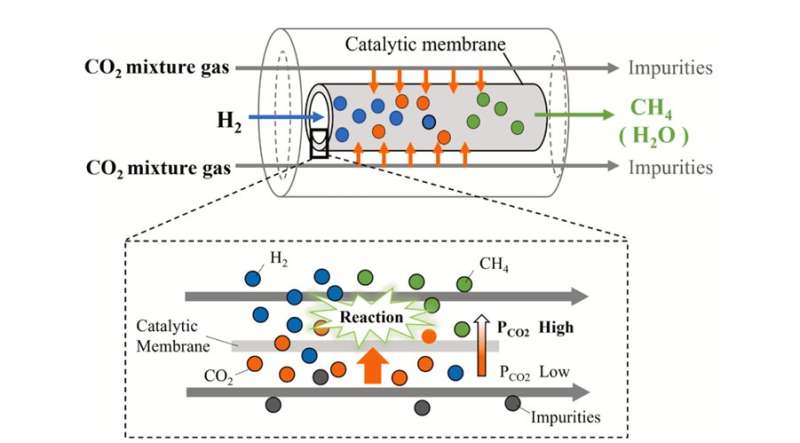

To implement this technique, a particular sort of membrane reactorreferred to as the distributor-type membrane reactor (DMR), is required that may facilitate chemical reactions in addition to separate gases. Whereas DMRs are utilized in sure industries, their utility for changing CO2 into methane, particularly in small-scale techniques like boilers, has remained comparatively unexplored.

This analysis hole was addressed by a gaggle of researchers from Japan and Poland, who had been led by Professor Mikihiro Nomura from Shibaura Institute of Know-how in Japan and Prof. Grzegorz Brus from AGH College of Science and Know-how in Poland. Their findings had been published within the Journal of CO2 Utilization.

The crew carried out a two-pronged strategy to the issue via numerical simulations and experimental research to optimize the reactor designs for environment friendly conversion of CO2 from small boilers into methane. Of their simulation, the crew modeled how gases move and react underneath totally different circumstances. In flip, this enabled them to attenuate the temperature variationsmaking certain that power consumption is optimized whereas methane manufacturing stays reliable.

The crew additional discovered that, in contrast to conventional strategies that channel gases right into a single location, a distributed feed design might unfold the gases out into the reactor as a substitute of sending them in from one place. This, in flip, ends in a greater distribution of CO2 all through the membrane, stopping any location from overheating.

“This DMR design helped us reduce temperature increments by about 300 degrees compared to the traditional packed bed reactor,” explains Prof. Nomura.

Past the distributed feed design, the researchers additionally explored different elements influencing the reactor’s effectivity and found that one key variable was the CO2 focus within the combination. Altering the quantity of CO2 within the combination affected how effectively the response labored.

“When the CO2 concentration was around 15%, similar to what comes out of the boilers, the reactor was much better at producing methane. In fact, it could produce about 1.5 times more methane compared to a regular reactor that only had pure CO2 to work with,” says Prof. Nomura.

Moreover, the crew investigated the affect of reactor dimension, discovering that rising the dimensions of the reactor facilitated the provision of hydrogen for the response. There was, nevertheless, a tradeoff to be thought-about as the advantage of greater hydrogen availability required cautious temperature administration to keep away from overheating.

The research thus presents a promising resolution to the issue of tackling a significant supply of greenhouse gas emissions. By using a DMR, low-concentration CO2 emissions might be efficiently transformed into usable methane gasoline.

The advantages gained should not restricted to methanation alone however can be utilized to different reactions, making this methodology a flexible instrument for environment friendly CO2 utilization even for households and small factories.

Extra data:

Yuya Sato et al, Unveil carbon dioxide recycling potential all through distributor-type membrane reactor, Journal of CO2 Utilization (2024). DOI: 10.1016/j.jcou.2024.102763

Offered by

Shibaura Institute of Technology

Quotation:

Combating carbon footprint: Novel reactor system converts carbon dioxide into usable gasoline (2024, Could 27)

retrieved 27 Could 2024

from https://techxplore.com/information/2024-05-combating-carbon-footprint-reactor-dioxide.html

This doc is topic to copyright. Aside from any truthful dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.