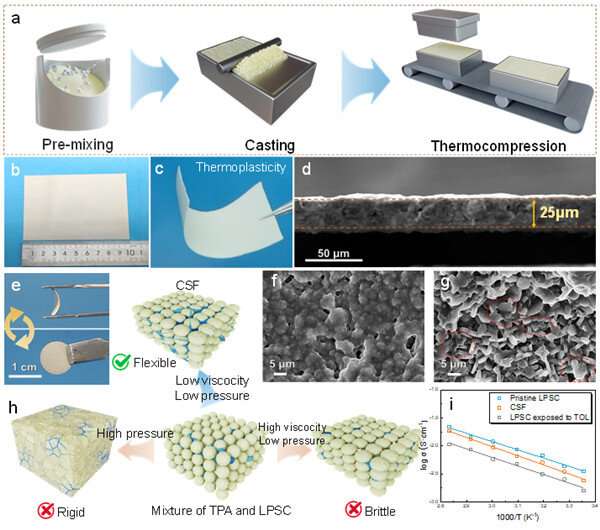

Schematic illustration of fusion bonding approach for dry-film course of and cross-sectional SEM photographs of composite sulfide movie. Credit score: Hu Le

The mixing of all-solid-state batteries with sulfide electrolytes is rising as a promising electrochemical system with potential advances in power density. The demand for skinny sulfides, particularly these with excessive flexibility, superior ionic conductivity, and robust interfacial stability, is crucial.

The prevailing desire for solvent-free expertise is nicely justified attributable to its environmental friendliness, cost effectivenessand suitability for thick electrode manufacturing. Nonetheless, the standard solvent-free technique, which primarily focuses on polytetrafluoroethylene fibrillation, has vital drawbacks comparable to poor adhesion, inadequate mechanical properties, and susceptibility to electrochemical instability.

Researchers led by Prof. Cui Guanglei from the Qingdao Institute of Bioenergy and Bioprocess Know-how of the Chinese language Academy of Sciences have developed a novel dry-film approach for the preparation of ultra-thin sulfide solid electrolytes and their integration with thick NCM83 cathodes in all-solid-state batteries via a sophisticated fusion bonding course of.

The studyrevealed in Superior Supplies on Might 4, demonstrates the profitable institution of a percolation community through a versatile polyamide binder with Li6PS5Cl via thermocompression, facilitating the manufacturing of ultrathin movies (≤25 μm).

The ensuing composite sulfide movie displays wonderful mechanical properties, a outstanding ionic conductivity of two.1 mS/cm, and a singular stress dissipation mechanism, which is essential for bettering interfacial stability.

Moreover, the synergistic mixture of improved interfaces and stress dissipation has resulted in distinctive biking efficiency. That is demonstrated by a capability retention of exceeding 80% after 707 cycles with a Li–In anode, nicely past the five hundred cycles required for sensible purposes.

As well as, the usage of the fusion bonding expertise has enabled the fabrication of strong LiNi0.83Co0.11Mn0.06O2 cathodes (~53.1 mg·cm-2) for the development of built-in all-solid-state batteries. This integration has resulted in a excessive energy density of 390 Wh·kg-1practically 1.5 instances increased than that of business lithium–ion batteries, and an prolonged cycle lifetime of greater than 10,000 hours.

“Our study underscores the significant practical application potential of fusion bonding technology, with profound implications for the future commercialization of sulfide all-solid-state batteries,” stated Prof. Cui.

Extra data:

Lei Hu et al, Fusion Bonding Approach for Solvent‐Free Fabrication of All‐Strong‐State Battery with Ultrathin Sulfide Electrolyte, Superior Supplies (2024). DOI: 10.1002/adma.202401909

Supplied by

Chinese Academy of Sciences

Quotation:

Novel dry-film approach developed for sulfide all-solid-state batteries (2024, Might 29)

retrieved 29 Might 2024

from https://techxplore.com/information/2024-05-dry-technique-sulfide-solid-state.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.