The high-density binders used to develop onerous carbon electrodes within the examine considerably improved the steadiness and fee functionality of sodium-ion batteries, paving the way in which for his or her commercialization. Credit score: Noriyoshi Matsumi from JAIST

Lithium-ion batteries have been on the forefront of power storage applied sciences. Nonetheless, the supply of lithium is proscribed. Consequently, the rising demand for energy-storage methods has led to the seek for low-cost and extra accessible supplies for rechargeable batteries. Sodium-ion batteries (SIBs) are a promising candidate because of the just about limitless sodium (Na) assets in seawater and salt deposits.

A lot analysis has been performed for enhancing supplies for optimistic electrodes (cathodes), damaging electrodes (anodes), and electrolytes for enhancing long-cycle stability and attaining a skinny strong electrolyte interface (SEI) for SIBs. An SEI is a passive layer shaped on the anode floor through the preliminary cost/discharge cycles, which prevents the anode from degrading on account of reactions with the electrolyte.

A well-formed SEI is essential for battery efficiency. On this context, onerous carbon (HC) has emerged as a promising anode materials. Nonetheless, its commercialization has been tough because it types an uneven, thick, and weak SEI on account of elevated electrolyte consumption, which lowers charging/discharging stability and response speeds.

To handle these points, binders akin to carboxymethyl cellulose salts, poly(acrylic acid) derivatives, and poly(vinylidene fluoride) (PVDF) have been used. Nonetheless, these binders trigger sluggish diffusion of Na ions within the anode, resulting in poor fee functionality of HC-based SIBs.

To beat these shortcomings, Professor Noriyoshi Matsumi and Doctoral Course Pupil Amarshi Patra from the Japan Superior Institute of Science and Expertise (JAIST) developed an HC anode utilizing a poly(fumaric acid) (PFA) binder. Their findings had been printed within the Journal of Supplies Chemistry A on Could 10, 2024.

Explaining the advantages of PFA, Prof. Matsumi says, “Unlike conventional poly(acrylic acid) binders, PFA is a high-functional density polymer with carboxylic acid present on all the carbon atoms of the main chain. This enables PFA to improve Na ion diffusion due to the presence of highly concentrated ion hopping sites and to adhere to the electrode more strongly. Additionally, PFA binders offer water solubility and non-toxicity, and its precursor, fumaric acid, is a bio-based polymer.”

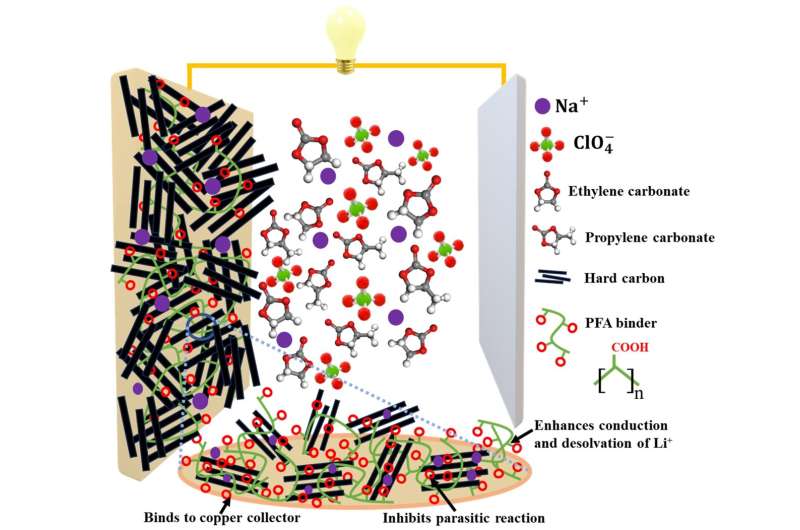

Polyfumaric acid binders enhance the diffusion velocity of ions and adhesion to the present collector of hard-carbon anodes in sodium-ion batteries, leading to wonderful biking stability and particular capability. Credit score: Noriyoshi Matsumi from JAIST

The researchers synthesized PFA via hydrolysis of poly(fumarate ester)s. Subsequent, they combined HC, Tremendous P carbon, and PFA in water to kind an aqueous slurry, which was coated onto a copper foil and dried in a single day to provide an HC anode. This anode, together with a sodium metallic disk because the counter electrode and 1.0 M NaClO4 because the electrolyte, was used to assemble an anode-type half-cell.

The researchers performed a peeling check to check the binder impact on adhesion between electrode parts and the copper present collector. Notably, robust adhesion is required for lengthy lifetime of SIBs. The peeling drive of the PFA-binder containing HC electrode was discovered to be 12.5 N, which was considerably greater than poly(acrylic acid)-HC electrodes with 11.5 N and PVDF-HC electrodes with 9.8 N of peeling drive.

The anode half-cell was subjected to numerous electrochemical and battery efficiency exams. In charging/discharging cycle exams, the anode half-cell confirmed particular capacities of 288 mAhg-1 and 254 mAhg-1 at present densities of 30 mAg-1 and 60 mAg-1respectively, considerably higher than PVDF and poly(acrylic acid)-type electrodes. It additionally confirmed wonderful long-cycle stability, retaining 85.4% of its capability after 250 cycles.

The anode shaped a skinny SEI and didn’t present crack formation or exfoliation, which contributed to the improved sturdiness of the half-cell. Moreover, the Na ion diffusion coefficient for the PFA-HC electrode was 1.9 × 10-13 cm2/s, greater than poly(acrylic acid)-HC and PVDF-HC electrodes.

These findings can result in the event of SIBs with improved electrochemical efficiency. Wanting in direction of the long run, Prof. Matsumi says, “In this polymer material, various structural modifications are possible through different polymer reactions, which can further improve performance. In the future, we aim to conduct joint research with companies for its commercial implementation. Additionally, as a water-soluble and non-toxic binder material that improves durability, it can not only be applied in SIBs but also in a wide range of energy storage devices.”

Total, this new materials can result in the extra widespread use of low-cost power gadgets based mostly on SIBs, resulting in a extra energy-efficient and carbon-neutral society.

Extra data:

Amarshi Patra et al, Water-soluble densely functionalized poly(hydroxycarbonylmethylene) binder for higher-performance onerous carbon anode-based sodium-ion batteries, Journal of Supplies Chemistry A (2024). DOI: 10.1039/D4TA00285G

Quotation:

Researchers develop new electrode binder materials for high-performance sodium-ion batteries (2024, Could 28)

retrieved 30 Could 2024

from https://techxplore.com/information/2024-05-electrode-binder-material-high-sodium.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.