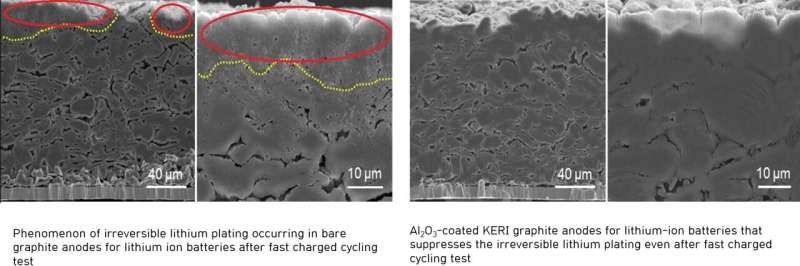

The cross-sectional SEM pictures of the cycled naked anode and Al2O3-coated anode for lithium ion battery. (left). Credit score: Korea Electrotechnology Analysis Institute (KERI)

A analysis crew has developed a core know-how to make sure the charging/discharging stability and long-life of lithium-ion batteries underneath fast-charging situations. Their findings were published in Superior Useful Supplies.

An important prerequisite for the widespread adoption of electrical autos (EVs) is the enhancement of lithium-ion battery efficiency when it comes to driving vary and security. Quick charging can also be important for consumer comfort. Nevertheless, growing the vitality density of lithium-ion batteries necessitates thicker electrodes, which may result in battery degradation and efficiency deterioration throughout fast charging.

To handle this situation, the KERI crew found an answer by partially coating the floor of the anode of the lithium-ion battery with aluminum oxide (Al2O3) particles smaller than 1 micrometer. Whereas many researchers worldwide have targeting the supplies throughout the electrode, comparable to introducing useful nanotechnology into anode materials like graphite, Dr. Choi’s crew employed a simple processing approach to coat the electrode’s floor with aluminum oxide.

Low in price, wonderful in electrical insulation and warmth resistance, chemically steady, and possessing good mechanical properties, aluminum oxide is extensively utilized in numerous ceramics.

Aluminum oxide dispersion (left) and anode for lithium ion battery coating it on. Credit score: Korea Electrotechnology Analysis Institute (KERI)

The KERI researchers discovered that aluminum oxide particles successfully management the interface between the anode and the electrolyte in lithium-ion batteries, forming an interfacial freeway for environment friendly Li+ transport. This prevents the electrodeposition of lithium (an irreversible change that makes the lithium unavailable for added charging and discharging) throughout quick charging, thereby guaranteeing the soundness and lifespan of the lithium-ion battery throughout charging and discharging.

One other benefit of this know-how is that it allows a rise within the vitality density of lithium-ion batteries. Introducing different useful supplies into the electrode’s inside to enhance efficiency and stability typically complicates the synthesis course of and reduces the quantity of reversible lithium (preliminary coulombic effectivity). It additionally will increase the electrode thickness, resulting in efficiency deterioration underneath quick charging situations.

Nevertheless, the KERI know-how entails floor therapy of the graphite anode, quite than modifying the inside lively graphite supplies. This method achieves steady efficiency even underneath quick charging situations for high-energy-density thick-film electrodes and not using a loss within the quantity of reversible lithium.

-

KERI Dr. Choi Jeong Hee is holding an aluminum oxide dispersion (left) and the anode for a lithium-ion battery coating it on the anode. Credit score: Korea Electrotechnology Analysis Institute (KERI)

-

KERI researchers are partially coating aluminum oxide on the floor of the anode of a lithium-ion battery. Credit score: Korea Electrotechnology Analysis Institute (KERI)

By way of numerous checks, the crew confirmed that the high-energy-density anode coated with aluminum oxide (4.4 mAh/cm2) reveals world-class efficiency, sustaining greater than 83.4% of its capability (residual capability ratio) even after 500 cycles of fast charging. They’ve verified this efficiency with pouch cells of as much as 500mAh. The crew is now planning to scale up the know-how to make it relevant to large-area, medium- to large-capacity cells.

The analysis crew was led by Dr. Choi Jeong Hee on the Korea Electrotechnology Analysis Institute (KERI) Battery Supplies and Course of Analysis Middle, in cooperation with a Hanyang College crew mentored by Professor Lee Jong-Gained and a Kyunghee College crew mentored by Professor Park Min-Sik.

“Convenient fast charging and the energy density of lithium-ion batteries have long been considered a trade-off, which has hindered the widespread adoption of electric vehicles,” mentioned Dr. Choi. “Our work will help develop stable, high-energy-density lithium-ion batteries capable of fast charging. This advancement will contribute to the wider adoption of EVs and support the achievement of national carbon neutrality.”

Patents have been registered in each Korea and the USA.

Extra info:

Jeong‐Hee Choi et al, Multi‐Interface Technique for Electrode Tailoring Towards Quick‐Charging Lithium‐Ion Batteries, Superior Useful Supplies (2024). DOI: 10.1002/adfm.202400414

Quotation:

Secure high-energy density lithium-ion batteries may result in quick charging electrical autos (2024, Might 31)

retrieved 31 Might 2024

from https://techxplore.com/information/2024-05-stable-high-energy-density-lithium.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is offered for info functions solely.