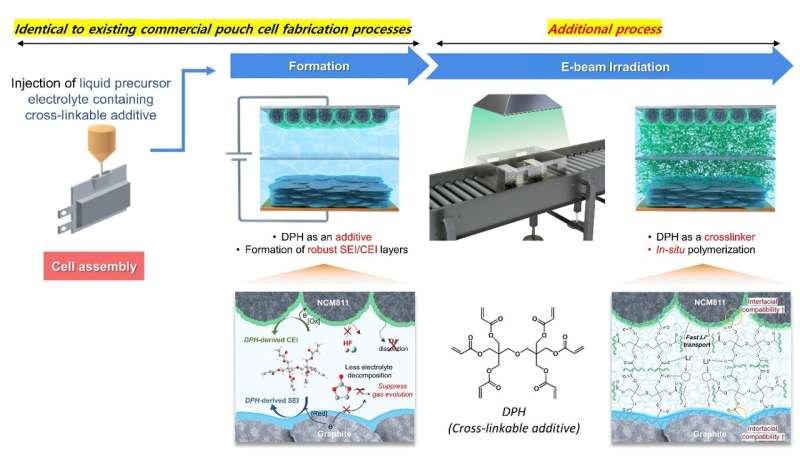

The manufacturing of pouch-type batteries with ultimate gel electrolyte is completed by following the similar manufacturing course of as typical business pouch cells, together with the formation and degassing steps, with the addition of an electron beam course of. Credit score: POSTECH

Professor Soojin Park, Seoha Nam, a Ph.D. candidate, and Dr. Hye Bin Son from the Division of Chemistry at Pohang College of Science and Know-how (POSTECH) have achieved a breakthrough in making a gel electrolyte-based battery that’s each secure and commercially viable. Their analysis was published within the journal Small.

Lithium-ion batteries are also used in transportable electronics and energy storagetogether with electric vehicles. Nevertheless, the liquid electrolytes utilized in these batteries pose a major threat of fireside and explosion, prompting ongoing analysis efforts to seek out safer options.

One different is the semi-solid-state battery, which represents a center floor between conventional lithium-ion batteries with liquid electrolytes and solid-state batteries. Through the use of a gel-like electrolyte, these batteries supply enhanced stability, power density, and a comparatively longer lifespan.

Creating gel electrolytes sometimes includes a protracted warmth therapy at excessive temperatures, which may degrade the electrolyte, resulting in diminished battery efficiency and elevated production costs. Moreover, the interface resistance between the semi-solid electrolyte and the electrode poses a problem within the fabrication course of.

Earlier research have encountered limitations in making use of their findings on to present business battery manufacturing strains resulting from complicated fabrication strategies and points with large-scale functions.

Professor Soojin Park’s crew tackled these challenges utilizing a bifunctional cross-linkable additive (CIA), dipentaerythritol hexaacrylate (DPH), mixed with electron beam (e-beam) expertise.

The standard pouch-type battery manufacturing course of contains the electrode preparation, electrolyte injection and meeting, activation, and degassing steps. Nevertheless, the researchers enhanced DPH’s twin performance by merely introducing an extra e-beam irradiation step after the degassing course of.

The CIA acted as each an additive to facilitate a secure interface between the anode and cathode surfaces throughout activation and as a crosslinker to kind a polymer construction in the course of the e-beam irradiation course of.

The crew’s pouch-type battery, using a gel electrolyte, considerably diminished gasoline technology from battery facet reactions throughout preliminary charging and discharging processes, reaching a 2.5-fold lower in comparison with typical batteries. Moreover, it successfully minimized interfacial resistance resulting from sturdy compatibility between electrodes and the gel electrolyte.

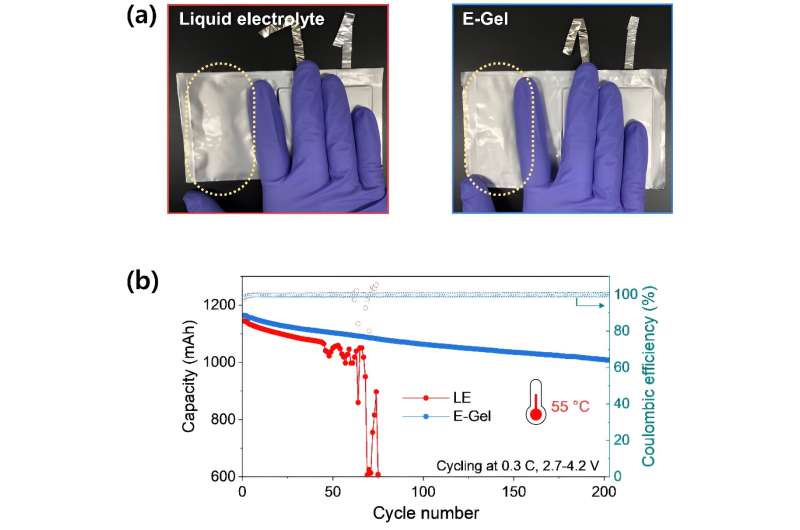

Subsequently, the researchers developed a high-capacity battery of 1.2 Ah (ampere-hour) and examined its efficiency at 55 levels Celsius, an surroundings that accelerates electrolyte decomposition. On this situation, batteries utilizing typical electrolytes skilled substantial gasoline technology, main a speedy discount in capability with swelling of the battery after 50 cycles.

In high-temperature evaluations of a high-capacity pouch cell (1.2 Ah), it was confirmed that the gel electrolyte (E-Gel) operates reliably even after 200 cycles, in comparison with business liquid electrolyte (LE). Credit score: POSTECH

In distinction, the crew’s battery confirmed no gasoline technology and maintained a 1 Ah capability even after 200 cycles, demonstrating its enhanced security and sturdiness.

This analysis is especially important as a result of it allows each the security and business viability of gel electrolyte-based batteries to be quickly mass-produced inside current pouch battery manufacturing strains.

Professor Soojin Park of POSTECH mentioned, “This achievement in stability and commercial viability is poised to be a breakthrough in the electric vehicle industry. We hope this advancement will greatly benefit not only electric vehicles but also a wide range of other applications that rely on lithium-ion batteries.”

Extra data:

Seoha Nam et al, Mitigating Fuel Evolution in Electron Beam‐Induced Gel Polymer Electrolytes By means of Bi‐Practical Cross–Linkable Components, Small (2024). DOI: 10.1002/smll.202401426

Supplied by

Pohang University of Science and Technology

Quotation:

Researchers develop a commercially viable and protected gel electrolyte for lithium batteries (2024, June 24)

retrieved 24 June 2024

from https://techxplore.com/information/2024-06-commercially-viable-safe-gel-electrolyte.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.