Schematic diagram of the one-step oxygen-generating electrode fabrication course of. Credit score: Korea Institute of Supplies Science (KIMS)

A analysis crew led by Dr. Sung Mook Choi of the Korea Institute of Supplies Science has developed a one-step electrode fabrication course of for the primary time in South Korea. The analysis is published within the journal Utilized Power.

This course of produces electrodesa key element of anion change membrane water electrolysisinstantly from raw materials to a mass-producible stage. The crew efficiently utilized this course of to a commercial-scale stack of anion change membrane water electrolyzer.

This technology makes use of a one-step hot-pressing course of that converts cobalt hydroxide right into a cobalt oxide catalyst whereas concurrently forming a extremely uniform catalyst layer. This technique replaces the complicated steps of the prevailing course of (hydroxide-oxide-crushing-dispersion-coating-drying) with a single coating step.

This achievement simplifies the method by 60% in comparison with the standard technique and permits the creation of a uniform catalyst layer. Moreover, it was confirmed that the effectivity of hydrogen manufacturing and the sturdiness throughout steady operation have been considerably improved.

To optimize the one-step electrode fabrication course of, the analysis crew efficiently fabricated a catalyst layer composed of uniform oxide particles, every 10 nanometers in measurement, by rigorously controlling the cobalt (Co) hydroxide slurry circumstances, in addition to the temperature and strain, that are key elements within the hot-pressing course of.

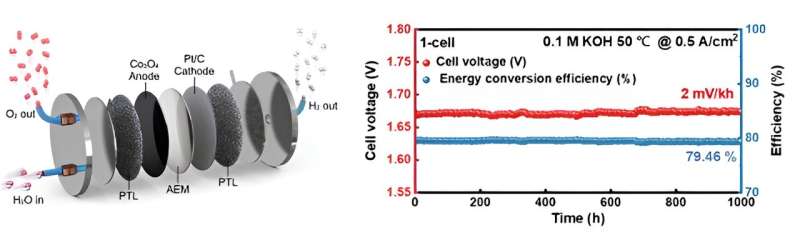

Moreover, the developed electrode was used to manufacture a membrane electrode meeting (MEA) incorporating an anion change membrane and a hydrogen evolution catalyst. Its stability and efficiency have been confirmed in a commercial-scale water electrolysis cell.

Schematic diagram of anion change membrane water electrolysis stack (left) and long-term sturdiness take a look at (proper). Credit score: Korea Institute of Supplies Science (KIMS)

By making use of the developed electrode to an anion change membrane water electrolysis system, the crew demonstrated the potential of attaining steady anion change membrane water electrolysis with excessive hydrogen era effectivity (roughly 80% primarily based on low particular calorific worth) and a low degradation charge (2 millivolts per kilowatt hour for 1,000 hours of steady operation).

Inexperienced hydrogen manufacturing from water electrolysis is predicted to succeed in 11 million tons and 69 gigawatts of capability by 2030. In Korea, efforts are underway to develop know-how for demonstrating a megawatt-level anion change membrane water electrolysis system by 2024, with the purpose of commercializing such a system by 2030.

At the moment, the home stage of anion change membrane water electrolysis know-how is roughly 70-80% of world-class requirements. This necessitates vital funding in associated fields and an pressing must safe core authentic know-how and localize the know-how.

By means of the event of this know-how, it’s anticipated that by securing the supply know-how for the electrode manufacturing course of that may be mass-produced, it will likely be potential to safe a worldwide edge in associated applied sciences, localize water electrolysis know-how, and create and dominate abroad water electrolysis markets.

Dr. Sung Mook Choi, a principal researcher, acknowledged, “By growing a one-step scorching urgent electrode fabrication course of with excessive course of reliability, we’ve got addressed one of many key challenges associated to the commercialization of anion change membrane water electrolysis.

“If this know-how is utilized, we anticipate that mass manufacturing of anion change membrane water electrolysis might be potential, considerably decreasing unit prices.”

Extra data:

Shin-Woo Myeong et al, Extremely sturdy and environment friendly anion change membrane water electrolyzer utilizing one-step fabrication of the built-in electrode by the hot-press course of, Utilized Power (2024). DOI: 10.1016/j.apenergy.2024.123650

Quotation:

One-step course of simplifies electrode fabrication for water electrolysis (2024, July 15)

retrieved 15 July 2024

from https://techxplore.com/information/2024-07-electrode-fabrication-electrolysis.html

This doc is topic to copyright. Aside from any truthful dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.