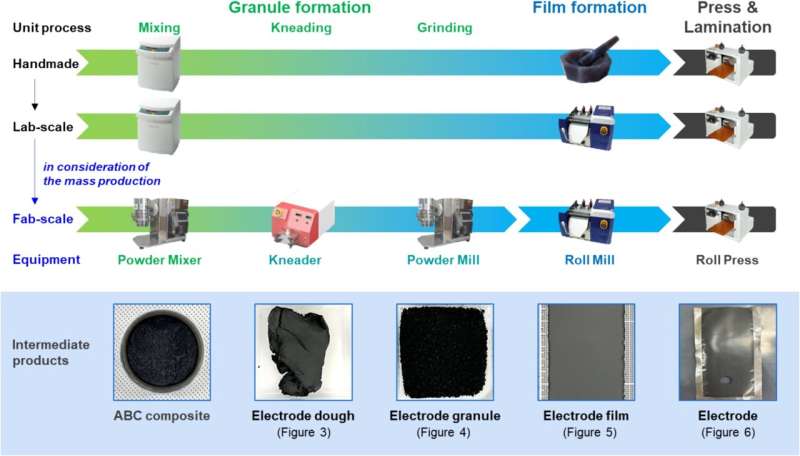

Overview of dry electrode manufacturing course of: unit processes, gear, and intermediate merchandise used on this research. Credit score: Chemical Engineering Journal (2024). DOI: 10.1016/j.cej.2024.151957

A group of researchers, affiliated with UNIST has made a big breakthrough in growing an eco-friendly dry electrode manufacturing course of for lithium-ion batteries (LIBs). The brand new course of, which doesn’t require using dangerous solvents, enhances battery efficiency whereas selling sustainability.

The findings of this analysis have been published within the July 2024 difficulty of Chemical Engineering Journal.

Led by Professor Kyeong-Min Jeong within the College of Power and Chemical Engineering at UNIST, the analysis group has launched a novel solvent-free dry electrode course of utilizing polytetrafluoroethylene (PTFE) as a binder. This progressive strategy addresses the challenges related to conventional wet-electrode manufacturing strategies, which frequently lead to non-uniform distribution of binders and conductive supplies, resulting in efficiency degradation.

The dry electrode course of is split into 4 phases: granule formation, movie formation, rolling, and lamination. The group optimized the method circumstances by evaluating the bodily, electrical, and electrochemical properties of semi-finished merchandise at every stage. The outcomes present {that a} high-extrusion-ratio PTFE binder can produce an electrode movie with excessive energy even with low power consumption, resulting in improved microstructure and energy traits.

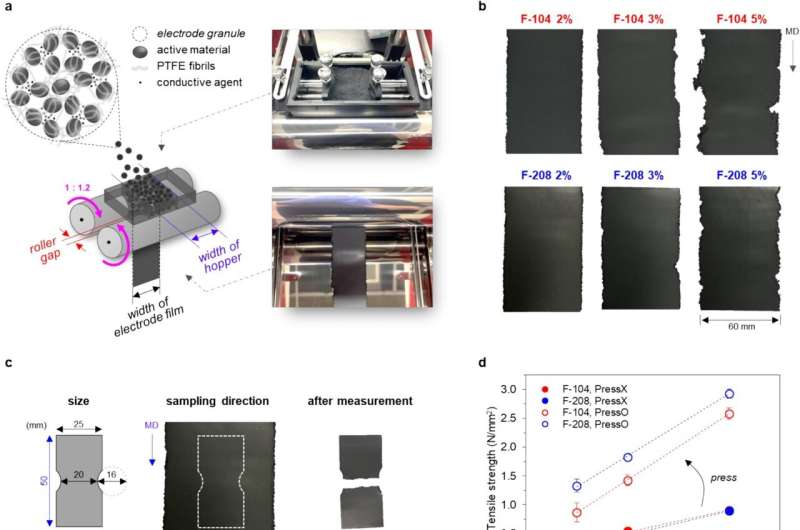

Movie formation—roll mill—electrode movie. (a) Schematic of the manufacture of electrode movie from electrode granules utilizing a roll mill. (b) Images of the electrode movie by kind and quantity of PTFE after roll milling. Credit score: Chemical Engineering Journal (2024). DOI: 10.1016/j.cej.2024.151957

In LIBs, binders play a vital position in connecting lively supplies and electrons. The research revealed that the sort and content material of PTFE binders considerably impression the output traits of dry electrodes. The researchers recognized an optimum formulation of NCM811/PTFE/carbon black (CB)/carbon nanotube (CNT) = 96/2.0/1.8/0.2, which demonstrated distinctive discharge price functionality of 80% at a 0.5 C-rate (5 mA/cm2) beneath demanding circumstances.

“This breakthrough will contribute to commercialization by providing a scalable and practical solution for mass production,” emphasised Professor Jeong. “We believe that our study will pave the way for environmentally friendly and efficient electrode manufacturing for future energy storage applications.”

The Korea Institute of Power Analysis (KIER) and Hanwha Co., Ltd. have additionally partnered with UNIST to develop dry electrode-specific manufacturing gear and display its industrial viability from the second half of 2024.

The group is planning to additional enhance the output traits of thick electrodes by exploring varied supplies by means of follow-up analysis. With this progressive expertise, electric vehicles and digital gadgets are anticipated to turn into extra sustainable sooner or later.

Extra info:

Hyeseong Oh et al, Improvement of a possible and scalable manufacturing technique for PTFE-based solvent-free lithium-ion battery electrodes, Chemical Engineering Journal (2024). DOI: 10.1016/j.cej.2024.151957

Quotation:

Examine unveils solvent-free dry electrodes that enhance lithium-ion battery efficiency (2024, July 19)

retrieved 19 July 2024

from https://techxplore.com/information/2024-07-unveils-solvent-free-dry-electrodes.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for info functions solely.