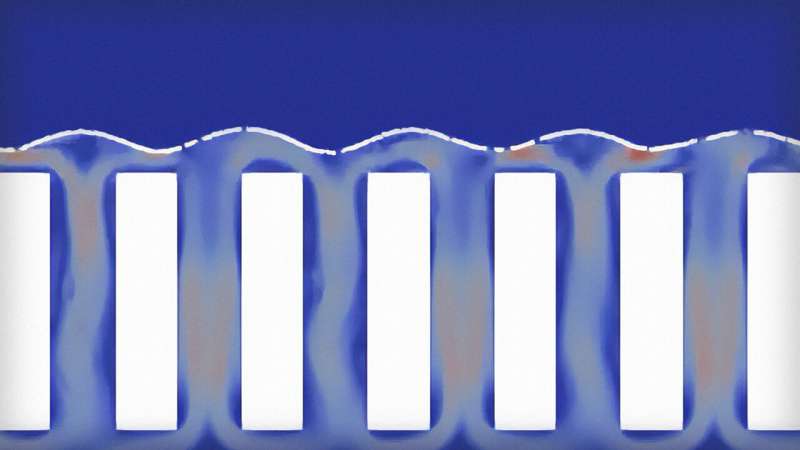

This screenshot from a pc simulation of the divertorlets system reveals the liquid steel because it travels across the slats within the machine, proven right here as white rectangles. Credit score: Francisco Saenz / PPPL

Fusion vessels have a Goldilocks drawback: The plasma inside must be sizzling sufficient to generate web energy, but when it is too sizzling, it could possibly harm the vessel’s inside. Researchers on the Princeton Plasma Physics Laboratory (PPPL) are exploring methods to attract away extra warmth, together with a number of strategies that use liquid steel.

One chance, say researchers on the U.S. Division of Vitality Lab, entails flowing liquid lithium up and down a sequence of slats in tiles lining the underside of the vessel. The liquid steel might additionally assist to guard the elements that face the plasma towards a bombardment of particles referred to as neutrons.

“The prevailing option for an economical commercial fusion reactor is a compact design,” stated PPPL’s Egemen Kolemen, co-author of a 2022 paper on the analysis and an affiliate professor of mechanical and aerospace engineering and the Andlinger Middle for Vitality and the Setting. Nonetheless, compactness makes dealing with the heat flux and neutron bombardment a much bigger problem.

“Currently, there are no available solid materials that can handle these loads. Flowing liquid metals have the potential to resolve these materials challenges.”

The liquid steel would solely be instantly uncovered to the plasma’s warmth very briefly because it traveled throughout the highest fringe of a skinny slat, pushed by magnetic forces and an electrical present. Then, the steel would flow down a channel created by the hole between two slats. Because the liquid steel descends towards the underside of the machine, referred to as a divertorlet, the liquid would cool. In the end, the liquid steel would journey again as much as the highest of a slat, collect warmth and fall once more.

Stream loops decrease the liquid steel misplaced to evaporation

Experiments on this prototype for the cooling system have been profitable, and the outcomes agreed with these proven in simulations. “We were able to replicate the flow loops around the slats, which is like the operational principle of the mechanism,” stated Francisco Saenz, a graduate pupil at Princeton’s Division of Mechanical and Aerospace Engineering and co-author of the divertorlets paper.

“In the system we propose, the liquid metal heats up at the top surface, but it is displaced almost immediately by cool liquid metal that comes to the top surface to keep absorbing heat,” Saenz stated.

With every rise and fall round a slat, the liquid would warmth up and get replaced with recent liquid steel. Nonetheless, the overheating of the liquid steel is minimized as a result of the liquid steel is barely uncovered to the warmth throughout its small journey over the divertorlet. Previous designs for related liquid steel techniques, referred to as divertors, concerned having the liquid steel stream instantly previous the plasma for an extended time period, which might have seemingly resulted in overheating and extra evaporation.

The lithium that strikes into the plasma by evaporation is also useful; primarily based on past research at PPPL, it ought to assist the plasma keep at excessive temperatures and be manageable.

“Lithium reduces the recycling of hydrogen particles. By recycling, I mean there are atoms from the plasma that leave the core, go to the walls and bounce back to the plasma,” Saenz stated. The isotopes that do bounce again have a considerably lowered temperature, which finally ends up cooling down the plasma’s temperature. “But if your plasma-facing system is made of lithium, it absorbs and keeps those particles that are colliding against the walls, so your plasma is no longer cooling down at fast rates.”

A mannequin of the divertorlet, with out the liquid steel. Credit score: Michael Livingston / PPPL Communications Division

The researchers used galinstan—a mixture of gallium, indium and tin—as an alternative of lithium of their experiments. “The electrical conductivity of a liquid metal is one of the governing properties for flows under the influence of strong magnetic fields, like those you would find in a fusion vessel. Galinstan has an electrical conductivity that is pretty similar to that of liquid lithium,” stated Saenz, which permits them to do evaluation of lithium flows in several situations.

The quantity of present utilized to the liquid was elevated in a sequence of steps to see how it could affect the velocity and uniformity of stream. Saenz stated the analysis staff achieved their goal velocity with out the liquid steel splashing. The sooner a liquid metal flows, the extra a particular type of power acts on it. This power, referred to as magnetohydrodynamic drag, slows the stream down.

Thankfully, their experimental outcomes aligned with what they noticed in simulations, and the researchers have been capable of get the liquid flowing beneath the 1 meter per second velocity restrict they set, utilizing 900 amps of electric current effectively. The perfect divertorlet would wish to not solely draw away warmth, Saenz stated, however accomplish that with out requiring an extreme quantity of energy to maintain the liquid flowing.

Princeton College graduate pupil Brian Wynne, who additionally labored on the divertorlets venture, is wanting ahead to future iterations of the prototype. “There is still more work to be done,” Wynne stated. “We need to optimize the structure of the geometry itself in terms of the shape of the slats.”

That may contain lowering the width of every slat and rounding the perimeters to cut back the peaks and valleys seen within the fluid. The height of 1 wave can block warmth switch to an adjoining valley, so making a clean floor ought to improve warmth absorption from the plasma to the liquid.

Wynne stated the following prototype may transfer from copper slats to 3D-printed tungsten, too. This extremely sturdy steel is regarded as nicely suited to plasma-facing elements, basically, so it’d make sense to make use of it for the divertorlets, he stated. Future prototypes additionally will examine techniques for flowing lithium out and in of the divertorlet. The present divertorlet prototype is a closed system, which means no liquid lithium was eliminated or added whereas the present was utilized.

Supplied by

Princeton Plasma Physics Laboratory

Quotation:

Creating loops of liquid lithium for fusion temperature management (2024, July 23)

retrieved 24 July 2024

from https://techxplore.com/information/2024-07-loops-liquid-lithium-fusion-temperature.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.