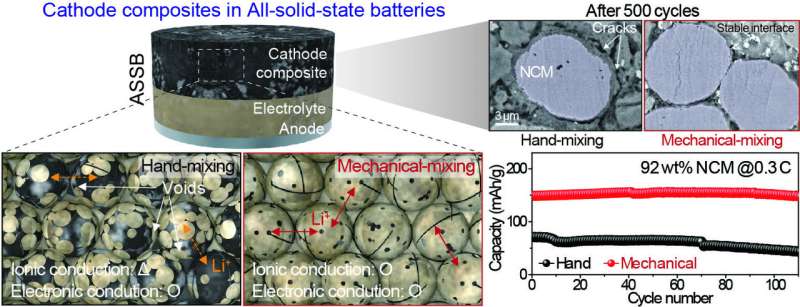

Schematic illustration of electrode buildings (optimum mechanical mixing vs. easy hand mixing) and comparability of the cell efficiency. Credit score: Korea Electrotechnology Analysis Institute

Researchers in Korea have united to sort out the challenges within the commercialization of all-solid-state batteries. The work is published within the journal Power Storage Supplies.

Dr. Yoon-Cheol Ha from the Subsequent Technology Battery Analysis Middle of KERI collaborated with a crew led by professor Byung Gon Kim of the Division of Utilized Chemistry, Kyung Hee College, a crew led by professor Janghyuk Moon of the Faculty of Power Methods Engineering, Chung-Ang College, and others, to develop a know-how to optimally combine cathode materials for all-solid-state batteries with sulfide stable electrolytes.

All-solid-state batteries are gaining consideration as a next-generation battery know-how on account of their extraordinarily low threat of fireside or explosion. Nonetheless, they require considerably extra superior know-how in comparison with standard batteries based mostly on liquid electrolytes, given the stable traits of the all-solid-state battery, making manufacturing tougher.

Specifically, the efficient combination and dispersion of cathode lively supplies with stable electrolytes, conductive components, and binders are recognized to be among the many challenges in manufacturing a composite electrode.

Stringent circumstances have to be met, reminiscent of creating channels (pathways) that facilitate the environment friendly switch of electrons and lithium ions and guaranteeing low interfacial resistance on the cathode-electrolyte interfaces.

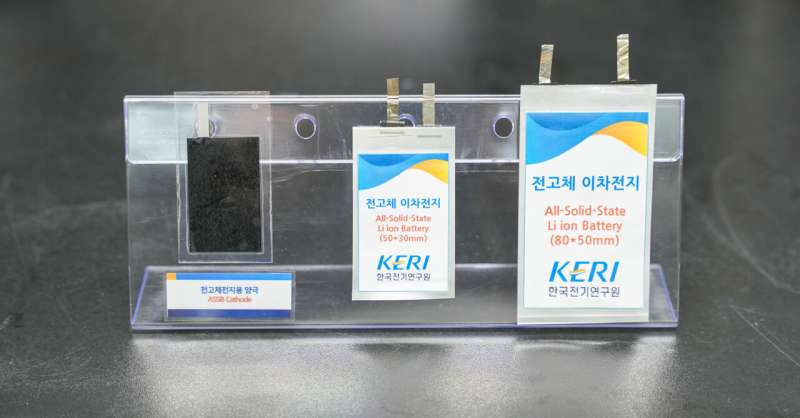

KERI’s all-solid-state battery with improved efficiency as a result of optimum design of cathode composite supplies. Credit score: Korea Electrotechnology Analysis Institute

Up till now, two most important strategies have been used to combine cathode supplies and solid electrolytes: merely mixing them mechanically in moist or dry conditions to make the thickness of tens to lots of of micrometers (one millionth of a meter), or utilizing the core-shell construction technique, the place the floor of cathode supplies is wrapped with stable electrolyte.

Nonetheless, these present strategies have confronted challenges in guaranteeing motion of electrons or ions and in forming a low-resistance interface.

As a way to resolve the problem, KERI and college analysis groups utilized the strategy of partially coating the cathode lively supplies with stable electrolyte.

Since sulfice stable electrolyte is delicate to oxygen and moisture and might deteriorate if misused, the analysis crew developed a blade mill-a particular gear that may make the most of inert gases that don’t trigger chemical reactions. This allowed them to review numerous sorts of stable electrolyte coating buildings and take a look at and confirm the optimum combination ratio and course of circumstances with cathode lively supplies.

KERI researchers, together with Dr. Yoon-Cheol Ha (far left), pose in entrance of the ‘blade mill’ gear used for the optimum design of cathode composite supplies for all-solid-state batteries. Credit score: Korea Electrotechnology Analysis Institute

The crew carried out numerous simulations to assemble intensive information demonstrating the development of the lively materials utilization (precise capability in comparison with theoretical capability) and fee functionality (quick charging/discharging in comparison with low present charging/discharging). They then utilized the end result to a prototype (pouch cell) to confirm the efficiency of the all-solid-state battery.

Dr. Yoon-Cheol Ha stated, “For the widespread adoption of all-solid-state batteries, it is important to enhance the performance and reduce the cost of the solid electrolyte itself. However, structural design and manufacturing process technologies that effectively create a composite electrode to facilitate the smooth flow of ions and electrons effectively are also important.”

He added, “By using a composite material where the cathode active material is partially coated with solid electrolyte at an optimal ratio, we can enhance the functionality of the electrode and significantly improve the performance of all-solid-state batteries.”

KERI, which has secured patents associated to the know-how, plans to seek out potential clients and pursue commercialization, believing that the achievement will appeal to vital consideration from producers of supplies and gear for all-solid-state batteries.

Extra info:

Yoon Jun Kim et al, Exploring optimum cathode composite design for high-performance all-solid-state batteries, Power Storage Supplies (2024). DOI: 10.1016/j.ensm.2024.103607

Quotation:

Advances in cathode composite design for sulfide-based all-solid-state batteries (2024, July 30)

retrieved 30 July 2024

from https://techxplore.com/information/2024-07-advances-cathode-composite-sulfide-based.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for info functions solely.