Credit score: Composites Science and Expertise (2024). DOI: 10.1016/j.compscitech.2024.110783

The widespread adoption of electrical automobiles tremendously depends on the event of strong and fast-charging battery applied sciences that may assist their steady operation for lengthy intervals of time. One proposed power storage resolution to enhance the endurance of electrical automobiles entails the usage of so-called structural batteries.

Structural batteries are batteries that may serve two functions, appearing each as structural parts of automobiles and energy storage options. As a substitute of being exterior parts which are added to an digital or electrical system, these batteries are thus straight embedded into the construction.

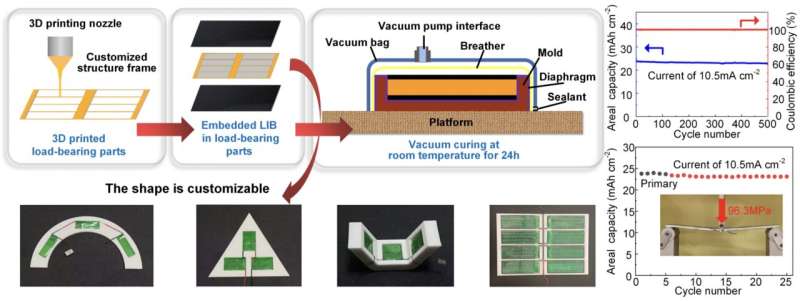

Researchers at Shanghai College and their collaborators lately devised a promising technique to fabricate extremely performing structural batteries with customizable geometric configurations. Their technique, outlined in a paper printed in Composites Science and Expertiseallows the 3D-printing of structural lithium-ion batteries for various geometrical configurations.

“This study aims to design an integrated energy storage and load-bearing structure with high load-bearing capacity and high energy storage,” Yinhua Bao, corresponding writer of the paper, instructed Tech Xplore.

“When it comes to designing structural power storage, material science primarily focuses on the synthesis and utilization of supplies, in addition to the secondary design of the parts for power storage.

“For example, carbon fiber frameworks or glass fiber frameworks can be utilized, and modifications can be made to the battery electrodes, separators, or electrolytes to enhance the load-bearing performance of the structural energy storage.”

Regardless of their potential benefits, many beforehand fabricated structural power storage options had been discovered to have vital limitations. These embrace comparatively low power densities and poor electro-mechanical biking efficiency.

As a part of their research, Bao and his colleagues got down to fabricate higher performing structural batteries utilizing a scalable fabrication technique. They particularly explored the potential of fabricating these batteries utilizing 3D printing, which is now extensively used to fabricate varied merchandise and digital parts.

“By leveraging 3D printing, we aim to create customizable structural frameworks that, when combined with energy storage materials, form components with integrated energy storage and load-bearing functions, featuring high energy density and load-bearing capacity,” Bao mentioned.

“The structural framework is intended to play the primary load-bearing role, minimizing or reducing damage to the energy storage materials during loadbearing, thereby ensuring excellent energy storage capacity.”

The structural framework launched by Bao and his colleagues may very well be tailored to allow the 3D printing of structural batteries for various functions, reaching past electrical automobiles. In reality, it is also used to supply structural power storage parts for particular autonomous robots and warehouse logistics automobiles.

The 3D printing technique devised by the researchers focuses on two key features of structural lithium-ion batteries. These are the power storage unit and structural framework.

“By designing a decoupled structure, it is possible to effectively reduce the deformation of the energy storage unit under load, thereby improving the mechanical stability of the battery,” Bao defined.

“We utilize 3D printing technology to create the framework, as it allows for rapid production and precise control of the structural components. We selected high-performance electrode materials and electrolytes to further enhance the energy density and cycle life of the battery.”

Bao and his colleagues additionally simulated the harm to an power storage unit underneath load utilizing finite factor software program. This allowed them to optimize the structural design of the batteries to restrict the expected harm.

“We also adopt a distributed arrangement of the battery cells to prevent the drawback of overall failure due to localized damage,” Bao mentioned. “Our tests demonstrate that by adopting a decoupled structural battery design approach, it is possible to achieve structural batteries with both high energy density and load-bearing capacity as well as mechano-electrochemical robustness. Furthermore, 3D printing technology enables the creation of customizable structural batteries.”

The researchers used their proposed method to manufacture a composite structural battery pattern. In preliminary checks, this battery was discovered to resist vital tensile and bending stress, whereas additionally exhibiting a excessive power density of 120Wh kg-1 and 210 Wh L-1 (3.5mA cm-2).

Notably, the battery was discovered to retain as much as 92% of its capability after 500 operation cycles. It additionally retained 98.7% of its capability underneath a tensile stress of 80MPa and 97% of its capability underneath a bending stress of 96.3 MPa, dropping roughly 0.18% of its capability per operation cycle.

“In practical applications, different material selections can be made for different components, and the use of finite element method simulations in real-world scenarios can optimize structural design,” Bao mentioned. “Our approach thus enables the fabrication of decoupled structural batteries to be applied across various use cases.”

Sooner or later, the 3D printing-based fabrication technique launched by this group of researchers might facilitate the large-scale manufacturing of extremely performing structural power storage parts for a variety of functions. These might embrace excessive capability and steady structural batteries for electrical automobiles, as nicely smaller scale batteries for robotic methods.

“The next step in our research will be to explore the application of decoupled structural batteries, such as unmanned aerial vehicles (UAVs) and robots,” Bao added. “We are going to make it more reliable by changing the material of structural frameworks.”

Extra data:

Xu Ma et al, Customizable 3D-printed decoupled structural lithium-ion batteries with steady cyclability and mechanical robustness, Composites Science and Expertise (2024). DOI: 10.1016/j.compscitech.2024.110783

© 2024 Science X Community

Quotation:

3D-printed decoupled structural lithium-ion batteries which are steady, strong and customizable (2024, August 19)

retrieved 19 August 2024

from https://techxplore.com/information/2024-08-3d-decoupled-lithium-ion-batteries.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.