Fortescue has launched its Inexperienced Metallic Venture in Pilbara, Western Australia. This US$50 million initiative, located inside the Inexperienced Vitality Hub at Christmas Creek, goals to provide over 1,500 tons of inexperienced steel yearly. With the primary output anticipated in 2025, this challenge marks a major development within the inexperienced hydrogen house.

Fortescue’s Hydrogen Plant: A Step In direction of Decarbonizing Mining

The iron and steel industry are extraordinarily troublesome to decarbonize, however the inexperienced mining chief is making groundbreaking efforts to cut back emissions on this sector.

Fortescue Govt Chairman Dr Andrew Forrest stated,

“Today is a celebration of innovation, collaboration, and stretch targets, and marks a pivotal moment in Fortescue’s journey to build a green metal supply chain. Iron and steel are the backbone of our infrastructure; however, traditional iron and steel production processes are among the largest sources of greenhouse gas emissions.”

So, what is that this inexperienced steel?

They’ve outlined inexperienced steel because the “end product resulting from processing iron ore into iron, using renewable energy and with near zero carbon emissions.”

Dr. Forrest additionally elaborated that the corporate’s present milestone marks the combination of inexperienced mining, large-scale renewable energy, and inexperienced hydrogen to provide inexperienced steel. He thinks it is a uncommon alternative to create a inexperienced provide chain and Fortescue is steading quick to reap the benefits of it.

The corporate’s newly put in inexperienced hydrogen refueling station acquired a serious increase of a $2 million grant from the Western Australian Authorities’s Renewable Hydrogen Fund. No marvel it’s main the inexperienced revolution, having huge green hydrogen capability.

Notably, this plant can produce as much as 530 kg of H2 fuel each day, equating to 195 tons yearly. It’s partly powered by photo voltaic vitality and may serve a fleet of 10 hydrogen-powered coaches. Talking of their newest developments, they’ve accomplished the most important mixed gaseous and liquid hydrogen plant on any Australian mine web site.

The Inexperienced Vitality Hub

Inexperienced hydrogen performs a vital position in decreasing mining emissions. It powers every little thing from buses to heavy tools like haul vans and excavators.

The Inexperienced Vitality Hub contains a hydrogen liquefaction facility, liquid hydrogen storage, and a liquid hydrogen refueling station. These are important elements in Fortescue’s broader decarbonization efforts, which additionally embody zero-emission prototypes.

Fortescue Hydrogen Programs (FHS)

The corporate desires a shift from fossil fuels through the use of renewable vitality to create cutting-edge hydrogen manufacturing methods for any software. Their portfolio consists of a variety of electrolyzer merchandise, methods, and companies, that includes superior applied sciences and membrane improvements. Fortescue’s hallmark PEM Electrolyzers use a Excessive-Strain Proton Alternate Membrane (HP PEM) because the core know-how.

For hydrogen options, they’ve FHS P50 that delivers 24,000 kg/day of high-quality, pressurized hydrogen by means of a modular however industrial-scale design. The opposite prototypes are FHS P1 and P5. They provide compact hydrogen options of capability 480 to 2,400 kg/day of high-grade hydrogen.

Fortescue’s Emissions Discount Targets and Technique

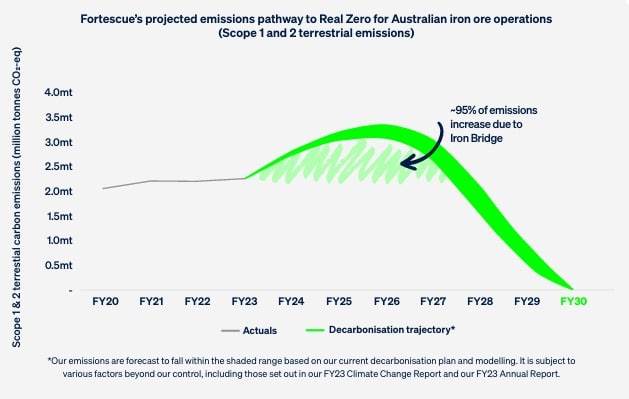

The corporate is dedicated to attaining actual zero Scope 1 and a couple of emissions throughout its Australian iron ore operations by 2030. It’s working in direction of having the targets verified by the SBTi for the present monetary 12 months. For Scope 3 emissions, Fortescue goals to decarbonize the steelmaking course of, transport, and upstream emissions by 2040.

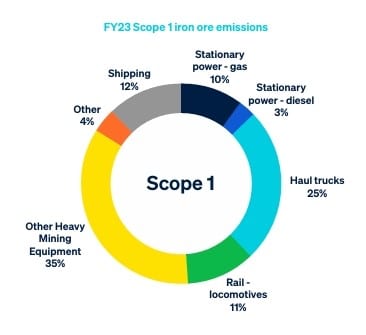

supply: Fortescue

- Scope 1 and a couple of Emissions: In FY23, Fortescue’s complete gross Scope 1 and a couple of emissions from Australian iron ore operations and marine vessels had been 2.55 mtCO2e. Scope 1 emissions had been 2.2 million tons, whereas Scope 2 emissions from energy purchases had been 0.35 million tons.

- Scope 3 Emissions: Fortescue’s Scope 3 emissions reached 267.61 mtCO2e in FY23, marking a 5% enhance from FY22 on account of an increase in iron ore shipments.

Since FY19, its RE use in Pilbara has grown from lower than 1 gigawatt hour (GWh) to 144 GWh in FY23, with a 58.9 GWh enhance since FY22. Immediately, renewable vitality accounts for 20% of the vitality bought for Pilbara operations.

The corporate’s local weather change technique is concentrated on three key areas:

- Implementing in-house and collaborative options to cut back emissions inside their iron-ore operations.

- Offering know-how options to deal with emissions throughout their worth chains.

- Driving the event of renewable vitality and inexperienced hydrogen to help international decarbonization efforts.

supply: Fortescue

Fortescue Metals Chief Govt Officer, Dino Otranto

“On decarbonization, we remain firmly committed to our target of Real Zero by 2030, without voluntary carbon offsets. Our hydrogen-powered haul truck prototype also operated on hydrogen for the first time and will soon be transported to our Christmas Creek site to undergo site-based commissioning and testing.”

Western Australia: The Inexperienced Hydrogen Hotspot

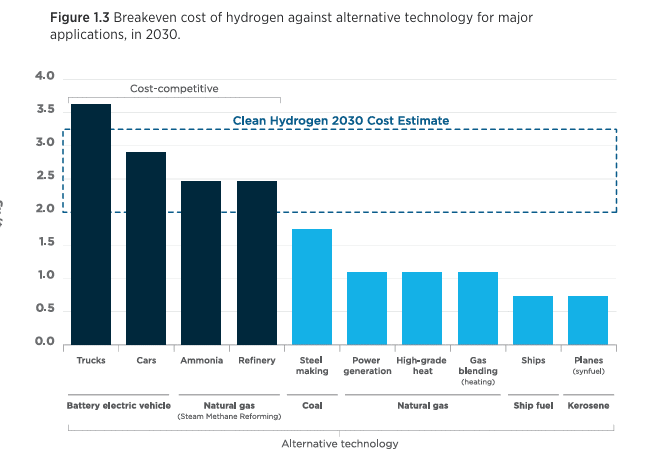

Australia leads the world in renewable hydrogen tasks. We dug right into a report in Hydrogen Perception and found that final 12 months the Australian Authorities introduced a subsidy of US$1.35bn to ramp up home inexperienced hydrogen provide.

They named it the “Hydrogen Headstart Program”. It goals to bridge the industrial hole for early-stage tasks, positioning Australia as a world chief in hydrogen manufacturing and export.

Furthermore, Western Australia (WA) is ideally positioned to provide, use, and export renewable hydrogen. It has ample renewable vitality assets, a strong vitality business, and proximity to main worldwide markets. These benefits make it a best choice for hydrogen buyers and firms.

Right here’s a report from Australia’s Nationwide Hydrogen Technique

supply: Australia’s Nationwide Hydrogen Technique

supply: Australia’s Nationwide Hydrogen Technique

Western Australia’s Premier, Roger Prepare dinner, hailed the plant as a vital step in rising as a world chief in clear vitality and inexperienced iron manufacturing. Thus, we are able to conclude that Fortescue’s new plant is really revolutionary. It produces each gaseous and liquid hydrogen, that may energy the corporate’s mining prototypes and coach fleet at Christmas Creek.