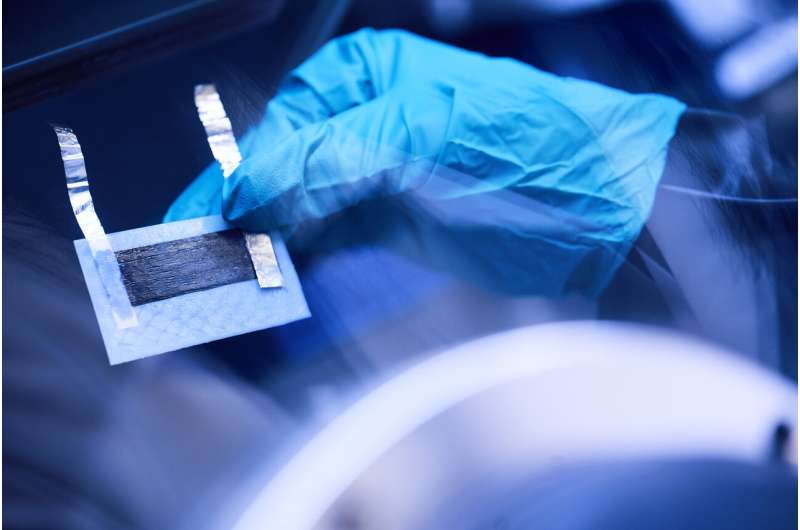

Researchers at Chalmers College of Expertise have succeeded in making a battery product of carbon fiber composite that’s as stiff as aluminum and energy-dense sufficient for use commercially. When vehicles, planes, ships or computer systems are constructed from a fabric that capabilities as each a battery and a load-bearing construction, the burden and power consumption are radically lowered. Credit score: Chalmers College of Expertise | Henrik Sandsjö

When vehicles, planes, ships or computer systems are constructed from a fabric that capabilities as each a battery and a load-bearing construction, the burden and power consumption are radically lowered. A analysis group at Chalmers College of Expertise in Sweden is now presenting a world-leading advance in so-called massless power storage—a structural battery that might halve the burden of a laptop computer, make the cell phone as skinny as a bank card or enhance the driving vary of an electrical automotive by as much as 70% on a single cost.

“We have succeeded in creating a battery made of carbon fiber composite that is as stiff as aluminum and energy-dense enough to be used commercially. Just like a human skeletonthe battery has several functions at the same time,” says Chalmers researcher Richa Chaudhary, who’s the primary writer of an article just lately published in Superior Supplies.

Analysis on structural batteries has been occurring for a few years at Chalmers, and in some levels additionally along with researchers on the KTH Royal Institute of Expertise in Stockholm, Sweden. When Professor Leif Asp and colleagues published their first results in 2018 on how stiff, robust carbon fibers might retailer electrical power chemically, the advance attracted huge consideration.

The information that carbon fiber can perform as electrodes in lithium-ion batteries was broadly unfold and the achievement was ranked as one of many 12 months’s ten largest breakthroughs by Physics World.

Decrease weight requires much less power

Since then, the analysis group has additional developed its idea to extend each stiffness and power density. The previous milestone was reached in 2021 when the battery had an power density of 24 watt-hours per kilogram (Wh/kg), which suggests roughly 20% capability of a comparable lithium-ion battery.

Now it is as much as 30 Wh/kg. Whereas that is nonetheless decrease than as we speak’s batteries, the situations are fairly totally different. When the battery is a part of the development and will also be product of a light-weight materials, the general weight of the automobile is drastically lowered. Then not practically as a lot power is required to run an electrical automotive, for instance.

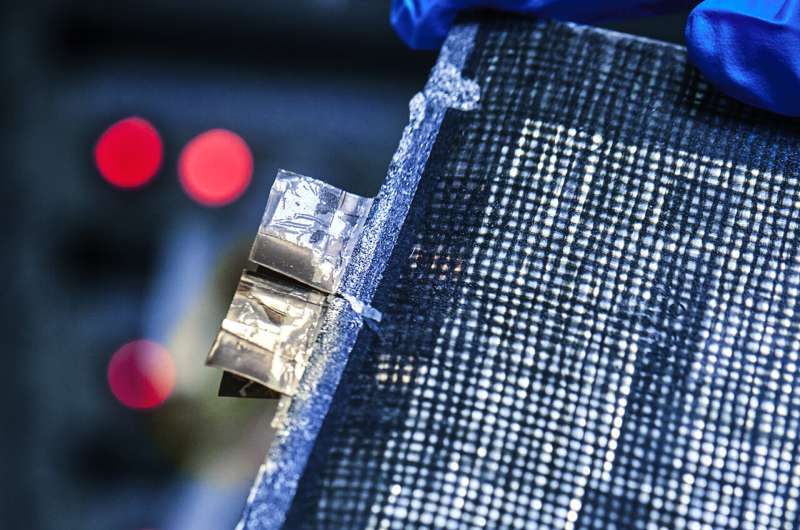

The developed battery idea relies on a composite materials and has carbon fiber as each the optimistic and destructive electrodes—the place the optimistic electrode is coated with lithium iron phosphate. The carbon fiber used within the electrode materials is multifunctional. Within the anode it acts as a reinforcement, in addition to {an electrical} collector and lively materials. Within the cathode it acts as a reinforcement, present collector, and as a scaffolding for the lithium to construct on. Within the picture, skinny present connectors are hooked up to the electrodes. Credit score: Chalmers College of Expertise | Henrik Sandsjö

“Investing in light and energy-efficient vehicles is a matter of course if we are to economize on energy and think about future generations. We have made calculations on electric cars that show that they could drive for up to 70% longer than today if they had competitive structural batteries,” says analysis chief Leif Asp, who’s a professor on the Division of Industrial and Supplies Science at Chalmers.

On the subject of automobiles, in fact, there are excessive calls for on the design to be sufficiently robust to satisfy security necessities. There, the analysis group’s structural battery cell has considerably elevated its stiffness, or extra particularly, the elastic modulus, which is measured in gigapascal (GPa), from 25 to 70. Because of this the fabric can carry masses simply in addition to aluminum, however with a decrease weight.

“In terms of multifunctional properties, the new battery is twice as good as its predecessor—and actually the best ever made in the world,” says Leif Asp, who has been researching structural batteries since 2007.

A number of steps in the direction of commercialization

From the beginning, the objective was to realize a efficiency that makes it doable to commercialize the expertise. In parallel with the truth that the analysis is now persevering with, the hyperlink to the market has been strengthened—by means of the newly began Chalmers Enterprise firm Sinonus AB, based mostly in Borås, Sweden.

Nonetheless, there may be nonetheless numerous engineering work to be performed earlier than the battery cells have taken the step from lab manufacturing on a small scale to being produced on a big scale for our expertise devices or automobiles.

“One can imagine that credit card-thin mobile phones or laptops that weigh half as much as today, are the closest in time. It could also be that components such as electronics in cars or planes are powered by structural batteries. It will require large investments to meet the transport industry’s challenging energy needs, but this is also where the technology could make the most difference,” says Leif Asp, who has observed an excessive amount of curiosity from the automotive and aerospace industries.

Researchers at Chalmers College of Expertise have succeeded in making a battery product of carbon fiber composite that’s as stiff as aluminum and energy-dense sufficient for use commercially. When vehicles, planes, ships or computer systems are constructed from a fabric that capabilities as each a battery and a load-bearing construction, the burden and power consumption are radically lowered. Credit score: Chalmers College of Expertise | Henrik Sandsjö

Extra in regards to the analysis and structural batteries

Structural batteries are supplies that, along with storing power, can carry masses. On this means, the battery materials can turn into half of the particular development materials of a product, which implies that a lot decrease weight will be achieved on, for instance, electrical vehicles, drones, handheld instruments, laptops and cellphones.

The newest advances on this space have been printed within the article “Unveiling the Multifunctional Carbon Fiber Structural Battery,” and the authors are Richa Chaudhary, Johanna Xu, Zhenyuan Xia and Leif Asp at Chalmers College of Expertise.

The developed battery idea relies on a composite materials and has carbon fiber as each the optimistic and destructive electrodes—the place the optimistic electrode is coated with lithium iron phosphate. When the earlier battery idea was offered, the core of the optimistic electrode was product of an aluminum foil.

The carbon fiber used within the electrode materials is multifunctional. Within the anode it acts as a reinforcement, in addition to {an electrical} collector and lively materials. Within the cathode it acts as a reinforcement, present collector, and as a scaffolding for the lithium to construct on.

Because the carbon fiber conducts the electron present, the necessity for present collectors product of copper or aluminum (for instance), is lowered, which reduces the general weight even additional. Nor are any so-called battle metals equivalent to cobalt or manganese required within the chosen electrode design.

Within the battery, the lithium ions are transported between the battery terminals by means of a semi-solid electrolyte, as an alternative of a liquid one, which is difficult in the case of getting high power and for this extra analysis is required. On the identical time, the design contributes to elevated security within the battery cell, by means of lowered danger of fireplace.

Extra info:

Richa Chaudhary et al, Unveiling the Multifunctional Carbon Fiber Structural Battery, Superior Supplies (2024). DOI: 10.1002/adma.202409725

Supplied by

Chalmers University of Technology

Quotation:

Carbon fiber structural battery battery paves means for mild, energy-efficient automobiles (2024, September 10)

retrieved 10 September 2024

from https://techxplore.com/information/2024-09-carbon-fiber-battery-paves-energy.html

This doc is topic to copyright. Aside from any truthful dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for info functions solely.