The success of the European pump sector in driving power financial savings was within the highlight on the latest EEMODS (Vitality Effectivity in Motor Pushed Programs) convention in Lucerne, Switzerland. An deal with by the president of Europump explored the adoption of the Prolonged Product Method (EPA), which is enabling system-level efficiencies in designs that make use of pumps.

Europump President Luboš Michlík delivered a presentation on the landmark technique and its related successes with industrial and industrial pumping programs.

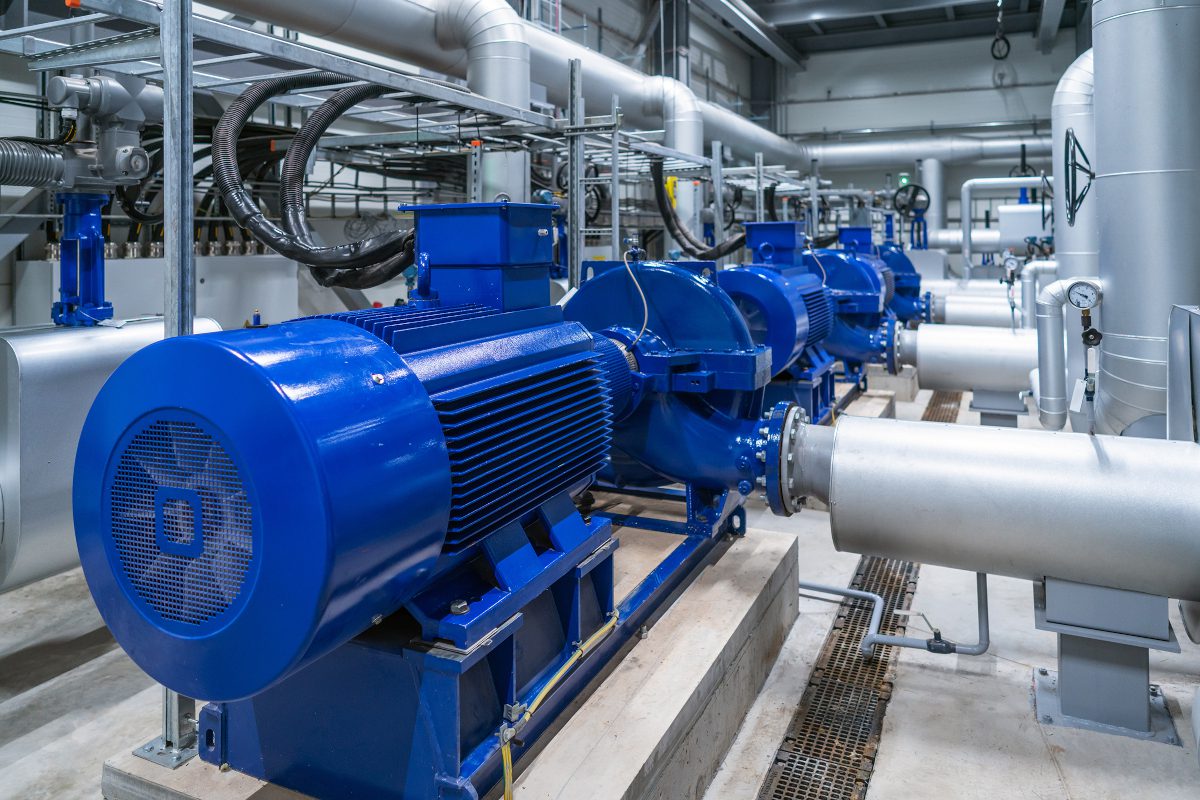

His deal with emphasised the significance of the pump sector in Europe’s total energy-saving efforts. He famous that pumps, which account for a considerable portion of power use in industrial functions, supply monumental potential for effectivity positive factors.

“The Extended Product Approach has revolutionised how we view and optimise energy efficiency within the pump sector,” stated Luboš Michlik. “Rather than focusing solely on individual pump performance, we now evaluate the entire system, including motors, drives, and control systems. This holistic view allows us to achieve far greater energy savings and system efficiency.”

The EPA methodology, developed and championed by Europump, shifts the main focus from particular person pump parts to the efficiency of the whole pumping system. By assessing how all components – pumps, motors, drives, and controls – work together, the EPA allows extra exact and impactful energy-saving alternatives.

Since 2016, these endeavours have resulted within the saving of 226 million MWh of electrical energy and a discount of 158 million tons of CO2 emissions. Moreover, the incorporation of the Prolonged Product Method into the upcoming revision of EU Regulation 547/2012 for water pumps may unlock an additional 35 TWh in power financial savings.

As a part of his presentation, Michlik highlighted a number of key achievements of the European pump sector beneath the Prolonged Product Method:

- Substantial Vitality Financial savings: By the adoption of EPA, industries have been capable of cut back the power consumption of pumping programs by as a lot as 20-30%, leading to important value financial savings and a smaller environmental footprint.

- Compliance with EU Rules: The pump sector’s dedication to power effectivity has aligned it carefully with the EU’s Ecodesign Directive, which units strict necessities for energy-using merchandise. The Prolonged Product Method has positioned the business on the forefront of regulatory compliance, demonstrating how proactive efforts can result in each financial and environmental advantages.

- Innovation and Sustainability: The deal with the entire system has pushed innovation throughout the pump sector, fostering the event of extra energy-efficient applied sciences and sensible programs that improve operational effectivity whereas lowering power demand.

Michlik additionally identified that the EPA mannequin serves as a blueprint for different energy-intensive industries seeking to make strides in power effectivity. The holistic method has been embraced by many throughout the sector and has develop into a key factor within the EU’s broader technique to scale back power consumption and mitigate local weather change.

“The success we’ve seen in the pump sector is only the beginning,” Michlik added. “Our work shows that by taking a systems-based approach, we can unlock much greater potential for energy efficiency in other sectors as well. This is not only good for businesses but for the environment and society as a whole. All we are waiting for now is official confirmation from the EU that the Extended Product Approach will be integrated into future ESPR / Ecodesign legislation, ensuring that even greater efficiency gains can be realised across Europe and beyond.”

The EEMODS convention, a premier world discussion board for discussing power effectivity in motor-driven programs, supplied the best platform for Europump to showcase the accomplishments of the European pump sector. The convention gathers policymakers, business leaders, researchers, and technical specialists to change data and promote methods that improve power effectivity.

Europump, which represents the European pump manufacturing business, continues to steer the cost in energy-saving initiatives by means of its advocacy, schooling, and technical innovation. Its efforts to advertise the Prolonged Product Method have been central to the success of the sector, and the organisation stays dedicated to additional advancing power effectivity throughout Europe and past.

For extra details about Europump and the Prolonged Product Method, go to https://www.europump.net/.