Volvo to Start Testing Hydrogen Combustion Engines in Vehicles by 2026

Volvo Vehicles is ready to make vital strides in the direction of its web zero emissions aim with the event of trucks powered by hydrogen combustion engines. Announced earlier this 12 months throughout the ACT Expo in Las Vegas, Volvo revealed plans to begin on-road checks with these modern vans by 2026, aiming for a industrial launch in the direction of the top of this decade.

Progressive Expertise

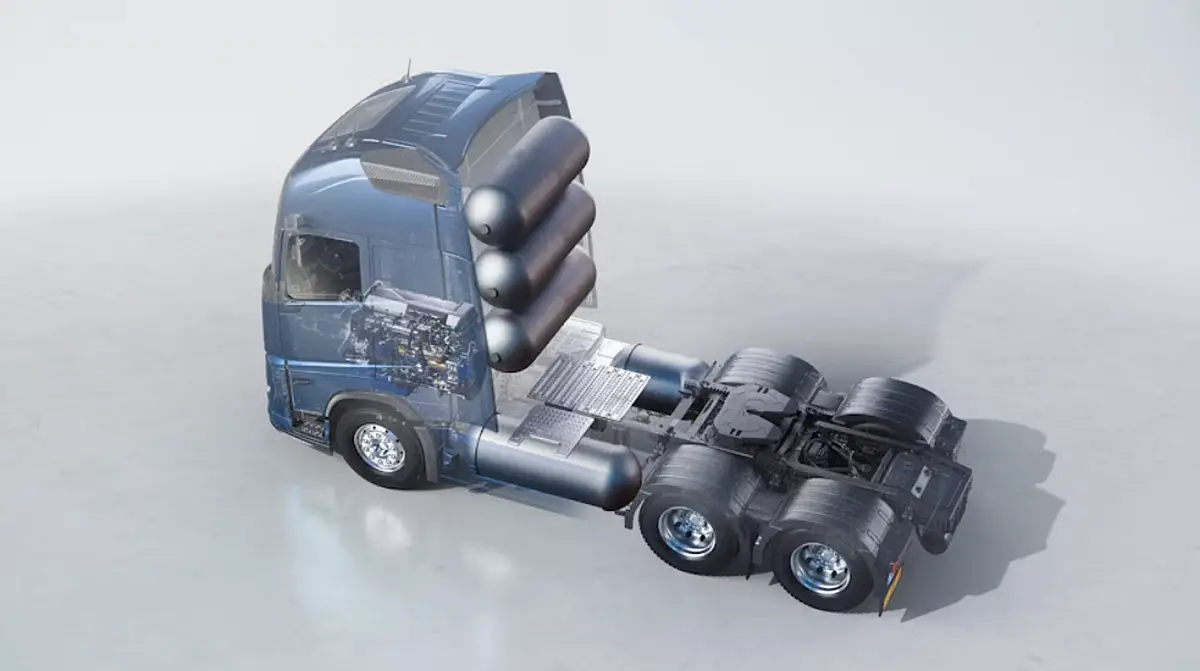

Volvo hydrogen truck 3d – Picture Credit score Volvo

The vans will characteristic Excessive Stress Direct Injection (HPDI) know-how, a complicated system the place a small quantity of ignition gasoline is injected at excessive stress to allow compression ignition earlier than the hydrogen is added. This technique ensures strong efficiency whereas sustaining effectivity and lowering emissions. Final 12 months, Volvo Group and Westport established a three way partnership to fast-track the commercialization of Westport’s HPDI gasoline system know-how for long-haul and off-road purposes.

How HPDI Expertise Works: Simplified

Westport’s H2 HPDI (Excessive-Stress Direct Injection) gasoline system is designed specifically for heavy-duty hydrogen engines, making it a robust and environment friendly various to conventional diesel engines. Right here’s a breakdown of the way it works:

- Gasoline Injection Course of:

- Pilot Gasoline Injection: The method begins with a small quantity of standard diesel gasoline being injected into the engine at excessive stress. This diesel acts as an ignition supply.

- Hydrogen Injection: Instantly after the pilot diesel is injected, hydrogen is instantly injected into the engine at a excessive stress.

- Combustion:

- The hydrogen burns utilizing a standard diffusion flame technique, which helps in reaching a clear and environment friendly combustion course of.

- Each the pilot diesel and hydrogen are injected by means of a specifically designed injector referred to as the twin concentric needle HPDI injector.

- Effectivity and Efficiency:

- By utilizing Diesel Cycle thermodynamics, the HPDI system working on hydrogen achieves greater thermal effectivity and energy density in comparison with normal diesel engines.

- The system not solely matches however doubtless exceeds the effectivity and efficiency of gasoline cells in a typical heavy-duty truck drive cycle.

- Environmental Influence:

- Emission Reductions:

- The H2 HPDI system reduces CO2 emissions by 95% in comparison with a base diesel engine.

- With additional refinements, emission reductions can attain upwards of 98%.

- Regardless of these vital reductions, a small quantity of diesel continues to be used to provoke combustion, stopping the system from reaching zero emissions.

- Efficiency:

- Energy and torque are elevated by 20% over the bottom diesel engine.

- Thermal effectivity is improved by as much as 10%.

- Gasoline effectivity and vary are similar to fuel-cell geared up vans.

- Price-Effectiveness:

- Gives near-zero greenhouse fuel emissions at a decrease price than fuel-cell or battery-electric automobiles.

- Notably useful for heavy-duty, long-haul trucking the place hydrogen is seen as the longer term zero-carbon gasoline.

- Emission Reductions:

- Benefits:

- Greater Energy/Torque: The system can ship as much as 30% extra energy and torque than conventional diesel engines.

- Improved Effectivity: It gives as much as a 5% enchancment in thermal effectivity over base diesel engines.

- Prolonged Vary: With an 80 kg hydrogen storage capability, it supplies an approximate vary of 800 km on long-haul journeys.

- Low Emissions: It achieves a 94% discount in CO2 emissions on the World Harmonized Transient Cycle (WHTC).

Apparently, Volvo plans to conduct buyer checks on their hydrogen combustion engine earlier than rolling out their gasoline cell system.

Westport Fuel Systems Overview

Westport Fuel Systems, headquartered in Vancouver, Canada, has a significant global presence with facilities across Europe and the United States.

Market Adoption and Growth

Westport’s HPDI technology has experienced substantial market adoption, especially in Europe:

- Thousands of HPDI trucks are operational.

- European HPDI sales have averaged over 100% growth per year for the past three years.

- Many European trucks using HPDI run on biogas or renewable natural gas, meeting stringent environmental regulations.

Specializing in fuel systems for low-carbon fuels, Westport operates in a competitive market with key competitors like Ballard Power Systems, Nuvera Fuel Cells, Kongsberg Automotive, and Plastic Omnium.

Upcoming Milestones and Environmental Impact of Volvo’s Hydrogen-Powered Trucks

Lab testing of these hydrogen-powered combustion engines is currently underway. The on-road tests scheduled for 2026 will be a critical milestone, validating the technology’s practicality and performance in real-world conditions. If successful, the commercial launch is anticipated towards the end of this decade, marking a significant leap towards zero-emission heavy-duty transportation.

While hydrogen combustion does produce low levels of NOx, Volvo’s trucks will be capable of delivering very low CO2 emissions when using renewable HVO (Hydrotreated Vegetable Oil) as the ignition fuel. Under the new EU CO2 emission standards, these trucks will be categorized as “Zero Emission Vehicles” (ZEV), making them a viable option for meeting stringent environmental regulations.

Economic and Practical Advantages

Hydrogen combustion engines can be marginally less efficient than hydrogen fuel cells under specific load conditions. However, they offer substantial economic advantages. These engines are significantly less expensive to produce and maintain, and they come with a lower payload penalty and reduced space requirements compared to fuel cell systems. This makes them a practical and cost-effective solution for the heavy-duty truck market.

Strategic Timing Aligned with Global Hydrogen Infrastructure Expansion

The release of HPDI-equipped trucks is well-timed with global advancements in hydrogen infrastructure. Countries are investing heavily in hydrogen fueling stations, such as the $900M project to create hydrogen plants and refueling stops in British Columbia, and the H2 Gateway project, which aims to establish 20 fill-up stations for hydrogen fuel cell vehicles. These developments ensure that the necessary support for hydrogen-powered transportation will be in place, making HPDI technology a practical and future-ready solution for long-haul trucking.

Conclusion

The HPDI system uses both hydrogen and a small amount of diesel to initiate combustion, maintaining the high compression ratio of a diesel engine. This boosts power and torque by 20% and improves thermal efficiency by up to 10% compared to traditional diesel engines. It also achieves near-zero greenhouse gas emissions at a lower cost than fuel-cell or battery-electric alternatives, making it ideal for long-haul trucking. By utilizing existing diesel infrastructure, HPDI ensures seamless integration, reliability, and compliance with global emissions regulations, offering advantages over other hydrogen combustion engines.

This is why we like this system: One key advantage of HPDI is its ability to use a small amount of ignition fuel to facilitate high-pressure hydrogen injection, resulting in higher thermal efficiency and significantly lower CO2 emissions compared to traditional combustion engines and other hydrogen technologies. We can’t wait to see these trucks in action. Follow us for more updates on hydrogen combustion engine technology!