Traditionally, the mass manufacturing of inexperienced hydrogen has not been seen as a viable different power answer for our local weather disaster. However latest technological developments in proton alternate membrane (PEM) electrolyzers provide new avenues for long-term viability and current an intriguing alternative for producers. Specialists have lengthy deemed electrolyzers as a central expertise for assembly our “carbon peak and neutrality” objectives, however substantive investments have lagged as a consequence of excessive manufacturing prices. What these latest developments reveal, nevertheless, is that the long-term viability of electrolyzers is nearer than many understand.

Because it at the moment stands, electrolyzers last more, function extra effectively and price lower than at any level within the expertise’s historical past. Though electrolyzers didn’t develop into a key machine in large-scale inexperienced hydrogen storage till the Nineteen Nineties, their emergence within the different power market has led to many new analysis and improvement (R&D) investments. Furthermore, with a 90% discount in uninstalled capital prices during the last 20 years, advocates can now convincingly argue that electrolyzers are the important thing to a sustainable power future.

Developments in Electrolyzer Know-how

There have been a number of essential developments made in electrolyzer expertise. Enhancements embrace thinner membranes, much less treasured metals, and optimization of designs.

Implementation of Thinner Membranes. Why are thinner membranes so essential? For starters, consultants have speculated that thinner membranes enable electrolyzers to provide 150% extra hydrogen or run at 10% decrease power consumption than conventional designs. This is because of the truth that thinner membranes scale back the general distance protons need to journey throughout the porous transport layer (PTL). Accordingly, thinner membranes are answerable for sooner ionic transportation and a rise in general manufacturing.

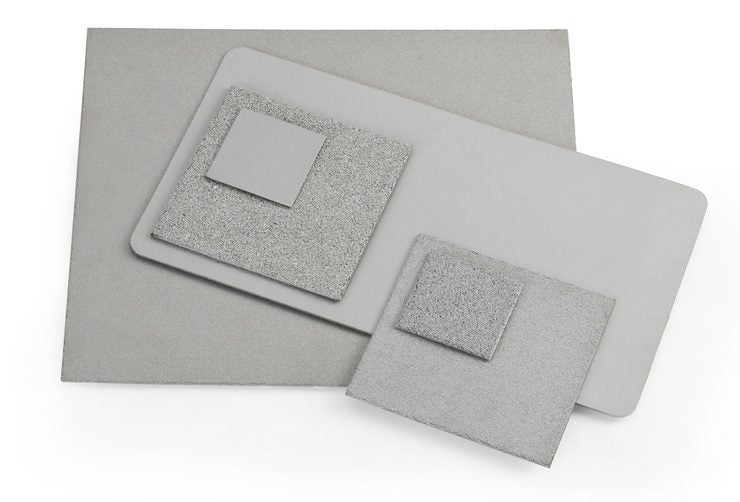

Probably the most environment friendly electrolyzer design, nevertheless, combines thinner membranes with the implementation of perforated titanium sheets as a substitute of standard felt supplies. Producer funding in PTL has led to the creation of titanium PTLs (Determine 1, titanium sheets) as skinny as 0.010″ that enable for decrease oxidation charges, smaller footprints, and higher resistance to bending and cracking. With this mix, PTLs can present higher thermal/electrical conduction and mechanical assist, together with pathways for each reactant liquid water supply to the catalyst layer and efficient gasoline removing from the response websites to the outlet.

Diminished Valuable Steel Coatings and Catalysts. Given the vital significance PTLs play in electrolyzer effectivity, limiting PTL deterioration is important for producers. Each the passivation of titanium and corrosion are restricted by treasured metallic coatings that defend the electrolyzer. Nonetheless, these coatings are sometimes handled with platinum group metals, and this generates important prices. Because of this, any try to make sure electrolyzer financial viability necessitates a unique coating technique—and this requirement has helped to drive titanium sheet improvement.

This answer has led to an infinite influence on manufacturing. A latest research discovered that skinny layers of iridium might be sprayed on titanium PTLs, thereby eliminating the necessity for platinum group metallic coatings. One key advantage of this method is improved electrical conductivity at a less expensive worth level. Finally, with reduced-iridium coatings, PEM electrolyzers have develop into considerably less expensive.

Optimization of Cell Design. Cells are vital for efficient electrolyzer processes as a result of they instantly contribute to an electrolyzer’s complete quantity of hydrogen gasoline storage; the extra cells producers can stack atop each other, the bigger the output. Optimizing cell design, subsequently, means making the cell processes themselves extra environment friendly in addition to bettering cell interactions within the stack.

Analysis groups have been working to optimize cell composition, resulting in new and modern designs. On the one hand, grooved electrode constructions have been confirmed to offer as much as 50% increased efficiency than current electrode designs whereas additionally enhancing the cell’s general sturdiness. On the opposite, analysis has proven that cell transport might be improved with novel alkaline water-splitting electrolyzers. In truth, there’s a case to be made that the most important enhancements left to be made with electrolyzer manufacturing lies with additional cell design optimization.

Extra Inexperienced Hydrogen Coming Quickly

In conclusion, the way forward for mass-production of hydrogen is nearer than many individuals acknowledge. Presently estimated at $185 billion, the inexperienced hydrogen market is ready to extend by greater than 600% over the following 25 years. This anticipated progress is reflective of the position inexperienced hydrogen is ready to play in our power future in addition to anticipated reductions in electrolyzer prices (an important promoting level for producers).

Nonetheless, this progress wouldn’t be doable with out the improved effectivity and prolonged lifespans which were achieved with latest electrolyzer developments. Electrolyzers might have probably the most hidden potential of any inexperienced power expertise—the one query is which producers are keen to capitalize.

—Mott Corporation contributed this text.