Ricardo’s Breakthrough in Hydrogen Gas Cell Know-how Marks a Leap Towards Clear Power

Ricardo, a world chief in engineering and clear vitality innovation, has hit a big milestone in inexperienced know-how. The corporate’s multi-stack hydrogen gas cell module achieved a exceptional 393 kW of web electrical energy inside solely three months of improvement. This achievement is a part of the Sustainable Hydrogen Powered Transport (sHYpS) undertaking, a key initiative beneath the European Union’s Horizon Europe program aimed toward decarbonizing the maritime sector.

What separates Ricardo’s gas cell system from others lies in its modular design. This revolutionary structure integrates a number of hydrogen gas cell stacks, leading to excessive energy density, scalability, and a zero-emissions vitality supply. The know-how is scalable for numerous purposes, together with maritime, rail, stationary energy, and off-highway vitality wants—providing a flexible answer for industries transitioning to greener operations.

Behind the Know-how: How Hydrogen Gas Cells Work

On the core of Ricardo’s success is the hydrogen gas cell, a system that makes use of electrochemical reactions to supply electrical energy. Hydrogen, fed into the gas cell, reacts with oxygen from the air, producing electrical energy and water vapor as its solely byproduct. There’s no combustion, no greenhouse gases—simply clear, renewable vitality.

Ricardo’s engineering group achieved this breakthrough utilizing their digital engineering toolchain. This superior framework reduces the time, prices, and dangers related to bodily prototyping. It additionally offers an in depth understanding of system efficiency beneath a wide range of situations, accelerating the event course of. For instance, the Ricardo group accomplished full transient ship operation take a look at cycles shortly after reaching most energy output, demonstrating the reliability and sturdiness of their system.

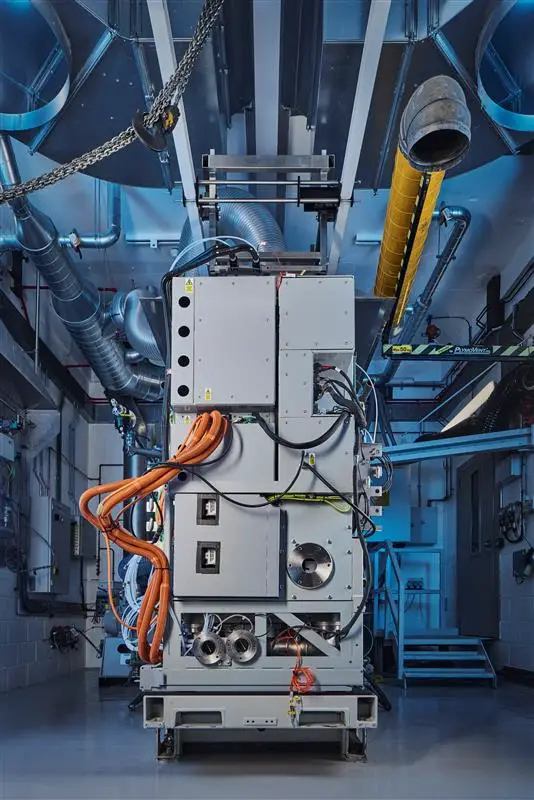

Ricardo’s hydrogen gas cell system – Picture Credit score Ricardo

Additional emphasizing security and adaptableness, Ricardo has secured Lloyd’s Register’s Approval in Precept, guaranteeing the system meets rigorous security requirements for ocean-going purposes. This step not solely advances maritime decarbonization but in addition opens the door for additional adoption throughout industries.

Containerized Options for Most Influence

To make hydrogen gas cells much more versatile, Ricardo has developed a containerized answer. This modular set-up permits a number of gas cell modules to be housed in customized containers, with built-in DC-DC energy conversion programs. A single container can obtain energy outputs of as much as 3 MW, whereas two containers mixed can produce 6 MW. To place that into perspective, that is sufficient energy to function a 50,000-tonne, 1,000-passenger cruise ship throughout zero-emission operations.

This transportation-ready design ensures that industries can scale up operations with out compromising effectivity or sturdiness. It’s an thrilling improvement, notably for maritime transport, the place clear vitality options have lengthy been restricted by technological and logistical constraints.

The Position of the sHYpS Challenge in Accelerating Hydrogen Adoption

The sHYpS undertaking, co-funded by the European Union and Innovate UK, performs a central function in advancing hydrogen applied sciences. Aiming to decarbonize the transport business and meet the Worldwide Maritime Group’s (IMO) 2030 and 2050 targets, the undertaking combines multi-disciplinary experience from companions throughout Europe.

Considered one of its key improvements is a novel swappable liquid hydrogen storage answer that integrates seamlessly into vessels. This enables simple refueling and ensures compatibility with totally different ship designs. By concentrating on scalable logistics, the sHYpS initiative can also be establishing a provide chain for liquid hydrogen in key ports, just like the Port of Bergen, to ease the transition for the transport business.

Projections for this technique present extensive adoption potential, with one Viking Ocean Cruise vessel already slated to check the hydrogen storage system throughout its shakedown voyage by 2026. And this isn’t a one-off—it’s estimated that a whole bunch of economic vessels, from river ships to deep-sea cruisers, may undertake related programs throughout the subsequent decade.

Ricardo’s hydrogen gas cell system introduces a number of notable options and developments that set it aside:

-

Modular Multi-Stack Design: In contrast to many conventional programs, Ricardo’s gas cell module integrates a number of stacks right into a single system. This modular structure permits for prime energy density and scalability, making it adaptable for numerous purposes, from maritime to stationary energy era.

-

Speedy Improvement Timeline: Attaining 393 kW of web electrical energy in simply three months from preliminary start-up is a testomony to Ricardo’s superior engineering processes. Their digital engineering toolchain performed a vital function in accelerating improvement whereas decreasing prices and dangers.

-

Containerized Options: Ricardo has developed a containerized system that mixes a number of gas cell modules, enabling energy outputs of as much as 6 MW when scaled. This design is especially fitted to large-scale purposes like powering cruise ships, providing a sensible and transportable zero-emission vitality answer.

-

Security and Certification: The system has obtained Lloyd’s Register’s Approval in Precept, guaranteeing it meets stringent security requirements for ocean-going purposes. This certification is crucial for adoption within the maritime sector, the place security is paramount.

-

Swappable Hydrogen Storage: As a part of the sHYpS undertaking, Ricardo is engaged on a swappable liquid hydrogen storage answer. This innovation simplifies refueling and enhances compatibility with numerous vessel designs, addressing logistical challenges in hydrogen adoption.

-

Versatility Throughout Industries: Whereas initially developed for maritime use, the system’s design is flexible sufficient to be utilized in rail, off-highway autos, and stationary energy era. This broad applicability makes it a game-changer for industries searching for to decarbonize.

-

Concentrate on Effectivity and Sturdiness: Ricardo’s system is engineered to take care of excessive effectivity and sturdiness, even beneath demanding situations. This ensures long-term reliability, which is essential for industries transitioning to hydrogen-based vitality.

-

Built-in DC-DC Energy Conversion: The inclusion of onboard DC-DC energy conversion of their containerized options enhances effectivity and simplifies integration into current programs

At this time, different sectors can begin leveraging containerized hydrogen fuel cell systems for stationary emergency backup energy or operations the place diesel mills dominate. City environments with excessive air high quality considerations may gain advantage from hydrogen-powered public transport programs. Over time, as infrastructure for hydrogen manufacturing and storage expands, the know-how might also grow to be a key driver for decarbonizing aviation and heavy business.

The timeline for widespread adoption depends upon the collective effort of innovators, policymakers, and industries to proceed supporting initiatives like sHYpS and scaling inexperienced hydrogen manufacturing. Ricardo’s groundbreaking engineering demonstrates that clear, high-powered options are potential, and with initiatives like these, the way forward for zero-emissions vitality is nearer than we would assume.