Breaking Floor in Renewable Vitality Innovation: SunHydrogen’s Quest for Inexperienced Hydrogen

SunHydrogen, a frontrunner in renewable hydrogen manufacturing, is making waves with developments in its nanoparticle-based know-how. Recent updates spotlight profitable large-area hydrogen module assessments performed in Japan, collaborations to drive innovation, and promising implications for world clear vitality manufacturing.

Document-Breaking Photo voltaic-to-Hydrogen Effectivity

Throughout their journey to Japan, the workforce performed groundbreaking tests on their hydrogen modulespushing the boundaries of inexperienced vitality know-how. On the College of Tokyo, beneath the steerage of specialists like Prof. Kazunari Domen, they trialed their 1200cm² hydrogen modules. These modules exhibited a outstanding 9% solar-to-hydrogen effectivity—a report for modules of this dimension.

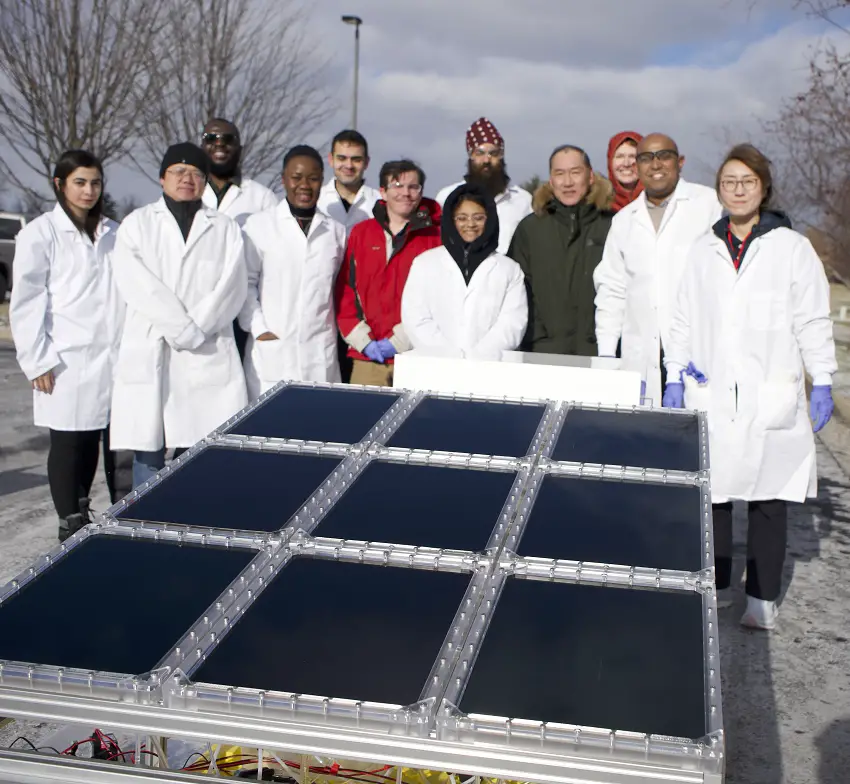

Picture Credit score – SunHydrogen

Beforehand, SunHydrogen achieved over 10% effectivity with smaller 100cm² modules, however scaling up introduces new challenges. Impressively, the bigger modules maintained excessive effectivity regardless of the complexities that include elevated scale. To high it off, these modules demonstrated stability throughout temperatures starting from 5°C to 40°C, utilizing a cutting-edge LED photo voltaic simulator that replicates photo voltaic vitality throughout substantial module areas. These outcomes sign that important strides are being made towards reaching scalable, dependable inexperienced hydrogen manufacturing.

Modern Collaborations with Honda and the College of Tokyo

Collaborating with Honda’s analysis and growth workforce has introduced extra worth to SunHydrogen’s efforts. At Honda’s Tochigi facility, SunHydrogen’s technology underwent real-world, outside assessments utilizing a singular rooftop setup. Honda’s membraneless module housing design is especially noteworthy. This innovation separates hydrogen and oxygen with out counting on environmentally persistent chemical substances like PFAS, paving the best way for safer and extra sustainable hydrogen manufacturing.

Honda is getting ready to duplicate on-sun assessments with SunHydrogen’s bigger 1200cm² modules, providing worthwhile efficiency knowledge. The suggestions loop from these collaborations is integral to refining SunHydrogen’s designs, making certain their modules can meet the calls for of commercial-scale manufacturing.

Again within the lab, SunHydrogen’s nanoparticle know-how is the bedrock of those developments. Borrowing ideas from photosynthesis, their Photoelectrosynthetically Lively Heterostructures (PAHs) use hundreds of thousands of tiny nanoparticles to separate water on the molecular degree. The consequence? Hydrogen fuel for clear vitality and oxygen as the one byproduct. This course of eliminates the necessity for exterior electrical energy, in contrast to conventional electrolyzers, making it an economical and sustainable various.

The Path Towards Scalable Options

SunHydrogen recognizes the need to scale up its technology while maintaining performance. Their scalable system of hydrogen-generating nanoparticles can be mounted in solar panels, enabling localized energy production. By partnering with CTF Solar GmbH, they’ve integrated thin-film solar cells to enhance the efficiency and durability of these hydrogen panels. Recent demonstrations of the 1m² panel have shown promising results, reinforcing the feasibility of large-scale deployment.

Adding to their strategic initiatives, the company has been evaluating potential pilot sites, collaborating with global industry leaders such as Honda R&D in Japan and COTEC in South Korea. These efforts reflect a larger commitment to transitioning their laboratory innovations into practical, on-the-ground solutions.

Why Green Hydrogen Matters Today

Green hydrogen presents an opportunity to rethink how we power industries, transportation, and even cities. Traditional hydrogen production often relies on fossil fuels, which negate the environmental benefits hydrogen could offer. SunHydrogen’s method flips that script by using only sunlight and water—a zero-carbon solution. By decentralizing hydrogen production through localized solar-hydrogen panels, they bypass the high costs of building extensive delivery infrastructure.

Looking at immediate applications, this technology could be integrated into hydrogen fuel stations, industrial manufacturing, and heavy transportation like shipping—a sector notoriously difficult to decarbonize. Over time, as production scales and costs decrease, we could see adoption expand into residential energy storage and off-grid living.

Trying to the Future

SunHydrogen’s recent advancements mark a step forward, but the road ahead includes fine-tuning and scaling this technology. Achieving efficiencies above 10% in large-area modules remains a goal as they refine designs and test materials. Wide-scale implementation might still be years away, but the trajectory is promising. Because they rely on abundant resources—sunlight and water—their approach holds the potential to democratize energy access across regions and populations.

While it’s easy to marvel at technological breakthroughs, what’s crucial is how such developments can be applied in everyday life. Imagine a farm running its machinery on locally produced hydrogen or a neighborhood charging vehicles with energy generated on-site. These scenarios are within reach if we continue with projects like this.

*The content provided in this article is for informational purposes only and is not intended to suggest any affiliation, partnership, or endorsement with SunHydrogen, Inc. All information has been compiled from publicly available sources to present insights into green hydrogen technology and its potential applications. This content does not constitute investment advice, financial guidance, or a recommendation to buy, sell, or hold any securities or assets. Readers are encouraged to perform their own research and consult with a qualified financial advisor before making any investment decisions.