NewHydrogen’s ThermoLoop Expertise Units New Requirements for Inexperienced Hydrogen

The race to a sustainable future is heating up, fairly actually, as firms like NewHydrogen, Inc. push the boundaries of innovation in renewable vitality. Their newest breakthrough, ThermoLoop™, guarantees to revolutionize inexperienced hydrogen manufacturing by using heat instead of electricitya important shift in making hydrogen extra reasonably priced and accessible. However how precisely does this know-how work, and what might it imply for the world’s vitality panorama? Right here, we break it down.

The Downside with Conventional Hydrogen Manufacturing

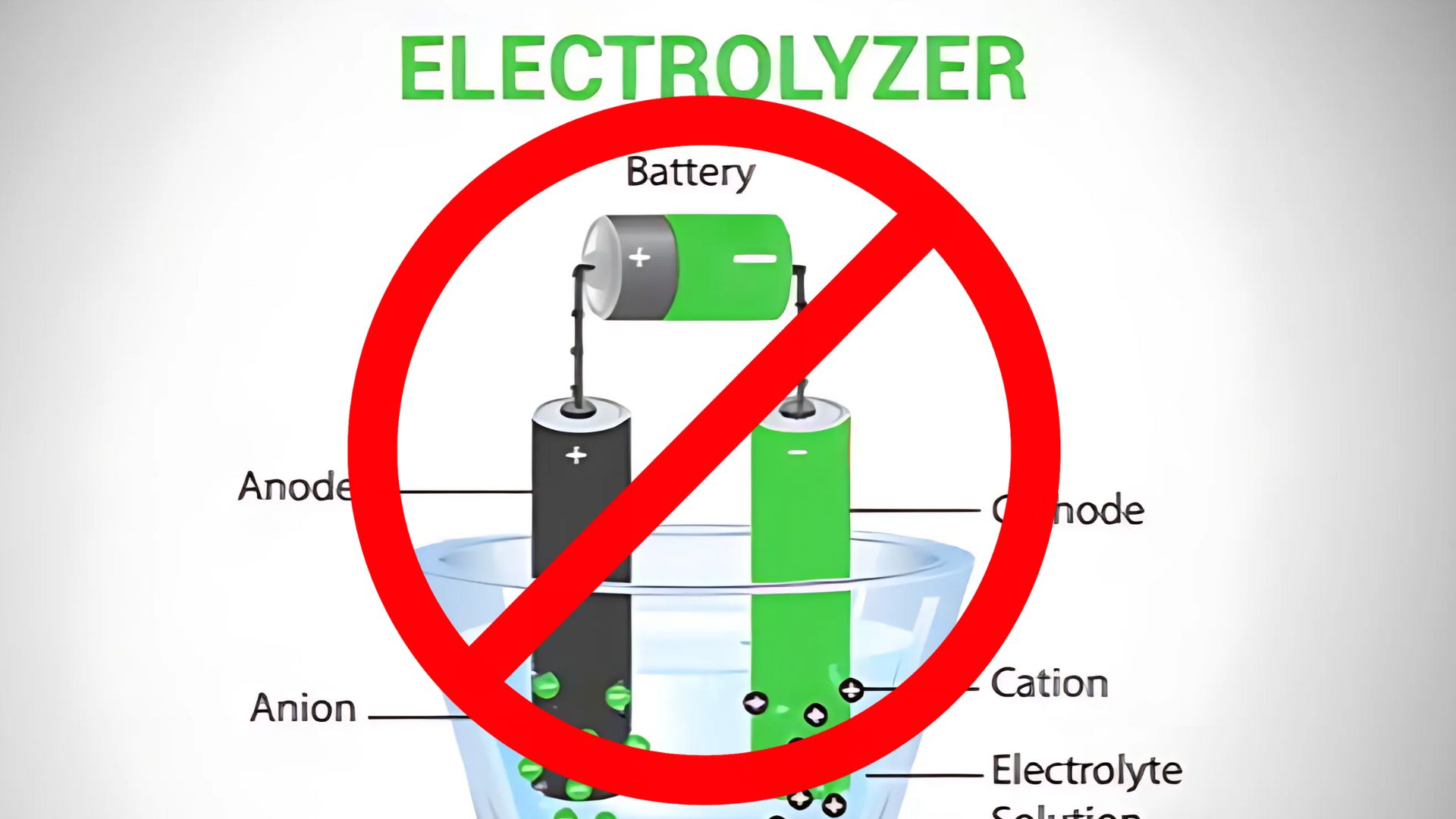

Hydrogen is heralded as a renewable vitality celebrity. It has the potential to energy gasoline cells, facilitate clear transportation, and supply an answer for long-term vitality storage. Nevertheless, present strategies of manufacturing inexperienced hydrogen include steep challenges. Most inexperienced hydrogen at present is generated by electrolyzers, which use electrical energy to separate water into hydrogen and oxygen. Whereas efficient, this course of is expensive, with electrical energy accounting for roughly 73% of the full manufacturing price.

The problem is much more urgent contemplating that a lot of the hydrogen we use isn’t inexperienced in any respect. As a substitute, it’s derived from fossil fuels like pure gasoline, which defeats the aim of transitioning to a sustainable vitality ecosystem. Till now, the excessive price of inexperienced hydrogen has been an impediment to its widespread adoption. ThermoLoop, NewHydrogen’s flagship know-how, is ready to alter that.

How Does ThermoLoop Work?

Conventional thermochemical strategies of hydrogen manufacturing face a big hurdle—temperature mismatch. The chemical reactions concerned in splitting water require vastly completely different temperatures, resulting in inefficiencies throughout heating and cooling intervals. That is the place ThermoLoop shines.

Reasonably than counting on typical electrolyzers, ThermoLoop introduces a system that allows “near isothermal reactions,” the place all needed chemical processes happen at virtually the identical temperature. This breakthrough minimizes downtime and conserves vitality, permitting hydrogen manufacturing to “loop” repeatedly. What makes this attainable is NewHydrogen’s growth of a singular materials with phase-changing properties, which means it might simply transition between strong, liquid, and gasoline states. This materials acts because the linchpin for synchronizing response temperatures, fixing a problem that baffled scientists for many years.

Remarkably, the corporate leveraged superior synthetic intelligence and machine studying to design this materials. By sifting by means of choices throughout the periodic desk, they recognized the perfect mixture of parts with the “just-right” attributes to unlock scalable, environment friendly thermochemical reactions. The end result? A system poised to ship the most affordable inexperienced hydrogen on the earth.

Past Idea: Integrating ThermoLoop into Actual-World Purposes

One of ThermoLoop’s key selling points is its versatility. Unlike current technologies, the system doesn’t rely solely on electricity or specific heat sources. It can harness concentrated solar power, geothermal heat, industrial waste heat from factories, and even nuclear reactors. CEO Steve Hill highlighted this flexibility in a recent announcement, saying, “ThermoLoop is agnostic to the sources of heat and water. This opens the door to hydrogen production in areas where other solutions might fail.”

Interestingly, NewHydrogen has also explored how green hydrogen can play a vital role in microgrids and smart grids. Partnering with prominent academics like Dr. Claudio Cañizares from the University of Waterloo, the company has studied how hydrogen’s long-term energy storage potential could stabilize areas with high variability in renewable energy output. For instance, in remote northern communities with prolonged winter darkness, hydrogen produced during sunny summer months could serve as a critical energy reserve.

Hydrogen’s ability to complement smart grid systems further underscores its importance. Smart grids integrate advanced control mechanisms to balance electricity demand and supply, and hydrogen fits seamlessly as a storage medium. Though it competes with batteries on some metrics, hydrogen excels in applications requiring long-duration energy storage and scalability.

Why This Issues for a Cleaner Future

The implications of ThermoLoop extend far beyond the confines of laboratory trials or corporate press releases. If successful, the technology could transform industries that heavily rely on hydrogen, like steel manufacturing, oil refining, and agriculture. Consider that producing ammonia for fertilizers—a staple in global food production—is one of the largest consumers of hydrogen. Cheaper green hydrogen powered by ThermoLoop could dramatically reduce the environmental cost of essential goods we take for granted.

On a broader scale, ThermoLoop could address significant pain points in our transition to renewable energy. By making green hydrogen more cost-effective, countries can reduce their reliance on fossil fuels and meet ambitious carbon-zero targets more quickly. Additionally, ThermoLoop’s ability to utilize heat from sources such as industrial waste or geothermal systems reinforces a circular economy approach, repurposing energy that would otherwise go unused.

Disclaimer

This content is intended for informational purposes only and does not constitute an endorsement or promotion of any company, product, or technology mentioned herein. It does not provide, nor should it be interpreted as, financial or investment advice. Readers are encouraged to conduct independent research and consult with a qualified financial advisor before making any investment decisions. The views expressed are based on publicly available information and are not a guarantee of future performance or outcomes.