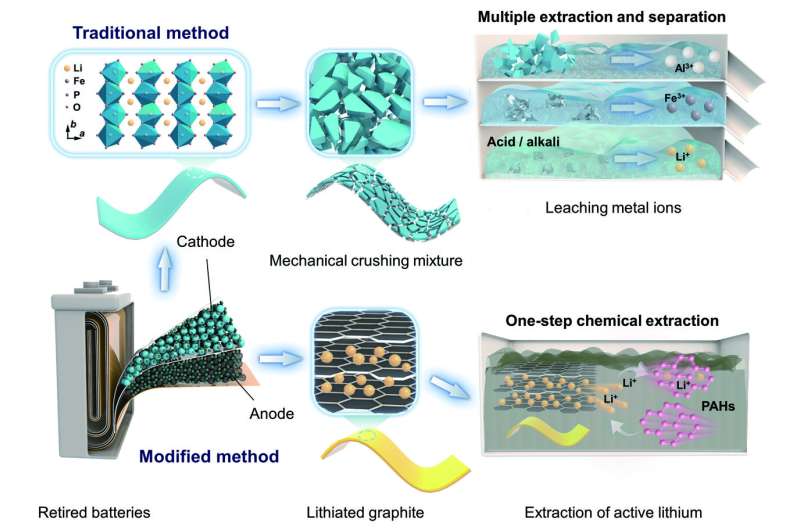

The standard hydrometallurgical methodology for recycling metals from spent lithium-ion battery cathode supplies includes advanced processes reminiscent of metallic leaching, precipitation, separation, and purification. An improved recycling strategy includes instantly chemically extracting energetic lithium from lithium-graphite anodes at room temperature. Credit score: Science China Press

Lately, the analysis findings of Professor Xie’s group (Huazhong College of Science and Expertise) were printed in Science Bulletin. This research proposed a easy, environment friendly, and low-energy chemical leaching technique, using a lithium extraction resolution composed of polycyclic fragrant hydrocarbon reagents and ether solvents to instantly extract energetic lithium from retired batteries.

Researchers screened a sequence of reagents with totally different redox potentials and solubilities based mostly on the molecular structural traits and studied their binding mechanisms with lithium.

Furthermore, by systematically analyzing the connection between the redox potential and extraction effectivity, coupled with theoretical calculation, the optimum reagent was chosen. The environment friendly restoration of energetic lithium from spent batteries was achieved by way of the optimization of solvent and course of parameters.

Notably, the recovered energetic lithium can function an important lithium supply. It may be instantly employed to react with iron phosphate by way of spontaneous redox reactions, thereby getting ready high-performance lithium iron phosphate supplies.

Physicochemical characterization and electrochemical efficiency exams confirmed the prevalence of the supplies ready by this technique. As well as, the recycling of lithium from business batteries enabled the large-scale preparation of lithium iron phosphate cathode supplies, demonstrating their sensible software prospects.

Importantly, lithium extraction options function inside a closed-loop system, minimizing the potential of environmental air pollution. As well as, the lithium extraction reagents could be recycled for reuse. In contrast with different recycling applied sciences, this method has good financial advantages and sensible prospects, and it’s anticipated to advertise the sustainable improvement of lithium-ion batteries.

Extra data:

Wei Liu et al, Direct lithium extraction from spent batteries for environment friendly lithium recycling, Science Bulletin (2024). DOI: 10.1016/j.scib.2024.02.034

Supplied by

Science China Press

Quotation:

Direct lithium extraction from spent batteries for environment friendly lithium recycling (2024, March 28)

retrieved 28 March 2024

from https://techxplore.com/information/2024-03-lithium-spent-batteries-efficient-recycling.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.