Lithium is an integral part in lithium-ion batteries which are primarily used in EVs and moveable digital devices. Typically often known as white gold as a consequence of its silvery hue, it is extracted from spodumene and brine ores. After mining it is processed into:

- Lithium carbonate is generally used in lithium iron phosphate (LFP) batteries for electrical automobiles (EVs) and power storage.

- Lithium hydroxidewhich powers high-performance nickel manganese cobalt oxide (NMC) batteries.

Diversifying Lithium Provide

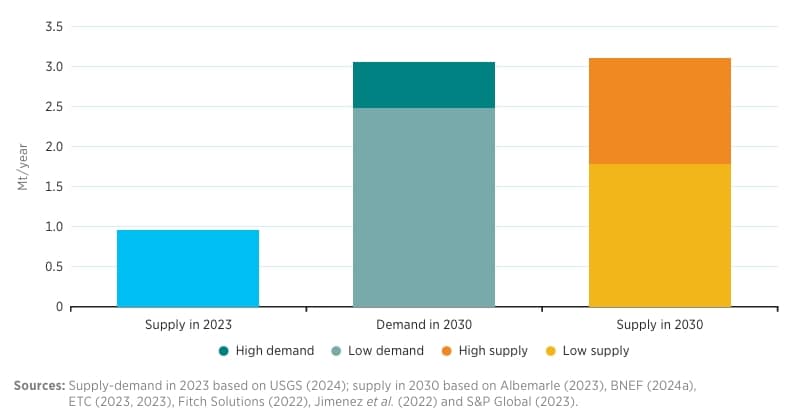

In line with IRENA’s 2024 version of the Critical Minerals Reportfinal yr world lithium manufacturing reached 0.96 million metric tons (Mt) of lithium carbonate equal (LCE) which might suffice short- to medium-term demand. However past 2030, recycling will play an important function in lithium provide, with 0.4 Mt of LCE anticipated to be accessible yearly by 2035.

Lithium provide and demand in 2023 and 2030

The report says that at current lithium mining is very concentrated, with over 90% sourced from AustraliaChile, and China. This has additionally led to world provide chain vulnerabilities.

Nevertheless, efforts to diversify manufacturing are underway, with nations just like the Democratic Republic of Congo, Germany, Ghana, and Portugal rising their investments in lithium exploration. These initiatives might assist cut back dependence on just a few dominant suppliers and unfold mining actions throughout the globe.

What’s Driving Lithium Demand?

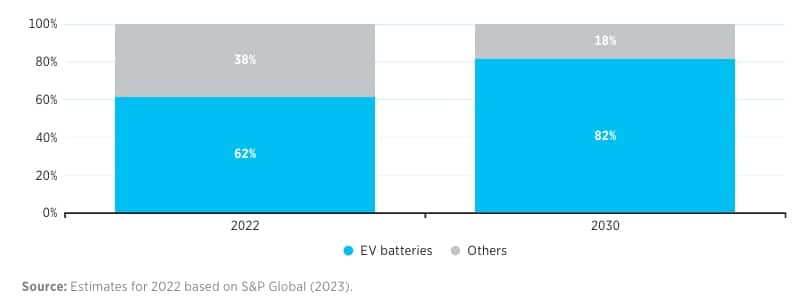

Despite the fact that now we have reported earlier, the reply stays the identical. It’s the EV market that’s primarily driving lithium demand. It’s projected to kind 82% of whole demand by 2030 which is a important enhance from 62% in 2022.

Different functions, resembling energy storage systemselectronics, and industrial makes use of, are anticipated to contribute between 0.43 and 0.60 Mt of demand yearly by 2030.

Assembly this rising demand would require a mining growth, diversified provide chains, and sturdy recycling methods to make sure a gentle and sustainable lithium provide for the longer term.

Lithium demand from EV batteries and different functions, 2022 and 203

Li-FT Power Ltd. (TSXV: LIFT) not too long ago introduced its first-ever Nationwide Instrument 43-101 (NI 43-101) compliant mineral useful resource estimate (MRE) for the Yellowknife Lithium Venture (YLP), situated within the Northwest Territories, Canada.

An Preliminary Mineral Useful resource of fifty.4 Million Tonnes at Yellowknife.

This maiden estimate is a significant milestone for the corporate and marks a big step ahead within the venture’s growth. Li-FT Energy’s upcoming mineral useful resource is anticipated to additional solidify Yellowknife as considered one of North America’s largest hardrock lithium assets.

Click to learn more about lithium and Li-FT Power Ltd. >>

________________________________________________________________________

EV Battery Manufacturing Set to Triple by 2030

- Lithium-ion battery manufacturing is anticipated to be 3X by 2030, rising from 2,000 GWh/yr in 2023 to 7,300 GWh/yr.

- This development will meet the EV battery demand of 4,300 GWh/yr by 2030 below a 1.5°C local weather state of affairs.

This projected development consists of operational factories, building tasks, and introduced plans. Nevertheless, some tasks are nonetheless ready for finalizing investments. These batteries gained’t simply energy EVs; they’ll additionally assist rising demand from power storage methods and moveable electronics.

As EV gross sales speed up, the demand for EV batteries is rising quickly. Passenger vehicles and vehicles are driving most of this demand as a consequence of their excessive gross sales volumes and the massive battery sizes required for vehicles. EV battery demand is anticipated to exceed 4,300 GWh yearly by 2030, representing a five-fold enhance in comparison with 2023.

Along with EVs, different sectors like battery power storage methods (BESS) are additionally rising battery demand. BESS demand is projected to develop six-fold between 2023 and 2030, however EV batteries will account for almost ten instances extra demand by the decade’s finish.

What Makes Up an EV Battery?

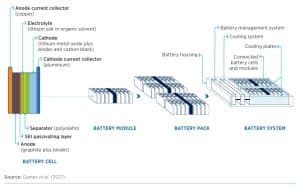

An EV battery is a pack of battery cells stacked collectively, comprising the next parts:

- Anode: Sometimes fabricated from graphite.

- Cathode: Typically composed of lithium steel oxides.

- Electrolyte: A liquid or strong lithium salt.

These parts work collectively to maneuver lithium ions throughout charging and discharging. This course of permits power storage and launch, powering the automobile.

Battery system parts and inner parts of a battery cell

EV Battery Chemistries: A Nearer Look

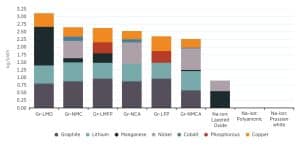

The cathode and anode characterize many of the crucial supplies in an EV battery. Cathode varieties fluctuate and embrace, Nickel Manganese Cobalt Oxides (NMC), Nickel Cobalt Aluminum Oxides (NCA), Nickel Manganese Cobalt Aluminum Oxide (NMCA), Lithium Iron Phosphate (LFP), and Lithium Manganese Iron Phosphate (LMFP). All these chemistries rely on lithiumhowever their compositions differ.

Now talking of EV battery anode, pure graphite is essentially the most broadly used materials. EV batteries sometimes use a mixture of pure and artificial graphite. The ratio is determined by the value, efficiency wants, and battery sort.

Copper is one other key materials in EV anodes. Copper foils act as present collectors, enjoying an important function within the battery’s operation.

These variations impression the selection of supplies, value, and environmental footprint and gasoline the demand for critical minerals within the EV battery business.

Estimated common crucial materials composition of chosen EV battery packs

Asia-Pacific Leads in EV Battery Manufacturing

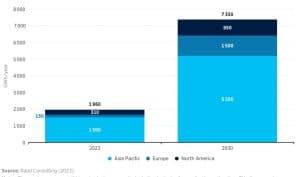

The Asia-Pacific area at the moment dominates world battery manufacturing, holding about 75% of capability. By 2030, this share is anticipated to dip barely to 70%, as different areas ramp up manufacturing. Europe is projected to see the quickest development, with a 10X enhance in capability between 2023 and 2030.

This fast growth highlights the worldwide push to assist EVs and different applied sciences, making certain the world strikes nearer to a cleaner power future.

Regional lithium-ion battery manufacturing capability in 2023 and deliberate capability for 2030

Supply: Knowledge and Visuals from IRENA: Critical materials: Batteries for electric vehicles