Elegant Techniques, a startup pioneering a revolutionary technique of manufacturing fossil-fuel-free cement, has been chosen by the U.S. Division of Vitality’s Workplace of Clear Vitality Demonstrations (OCED) to begin negotiations for as much as $87 million in funding beneath the Bipartisan Infrastructure Legislation and Inflation Discount Act.

The funding, a part of the Industrial Demonstrations Program, goals to assist initiatives like Elegant’s First Industrial Electrochemical Cement Manufacturing initiative. Chosen amongst 33 initiatives spanning over 20 states, these initiatives collectively obtain as much as $6 billion to showcase their commercial-scale decarbonization options.

These efforts are essential for transitioning energy-intensive industries in direction of net zero emissions. They will additionally assist bolster native economies, generate high-quality jobs, and mitigate dangerous emissions detrimental to public well being.

Cement’s Carbon Problem

To know the modern strides of Elegant Techniques, it’s essential to know the traditional cement-making course of and its environmental hurdles.

Cement, when blended with water, sand, and gravel, constitutes concrete, the second most consumed substance globally after water. This course of has remained largely unaltered for hundreds of years.

Sadly, producing conventional cement contributes considerably to carbon emissions, accounting for about 8% of the world’s complete emissions. That’s as a result of utilizing unusual Portland cement (OPC) course of to fabricate conventional cement depends on fossil-fueled kilns working at excessive temperatures.

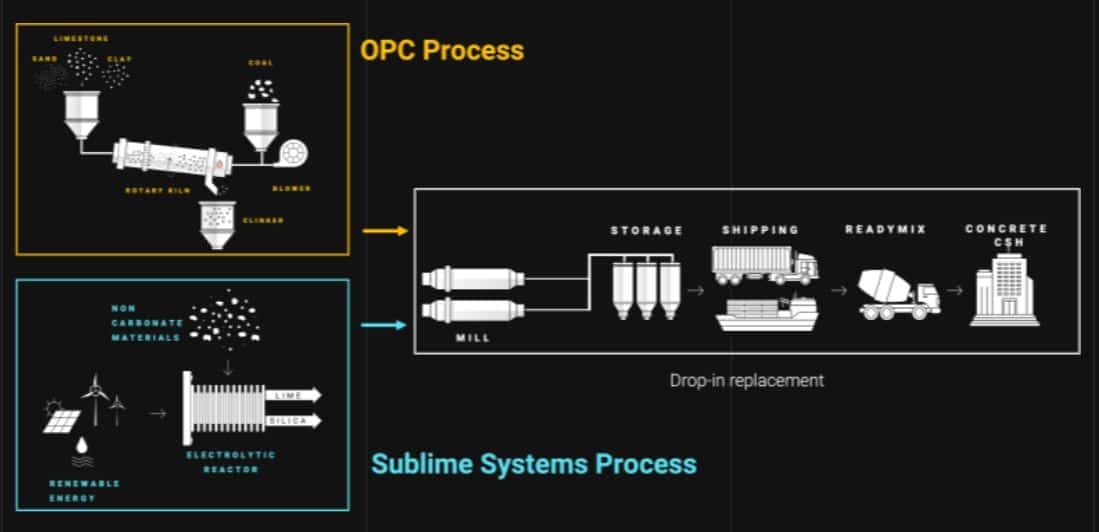

That is what Sublime Systems will attempt to deal with. Based in 2020, the Massachusetts-based firm works with a transparent mission – to revolutionize cement manufacturing and mitigate its environmental influence. Right here’s the Elegant means of cement manufacturing:

By means of modern electrochemical processes, Elegant has scaled up its cement manufacturing to a pilot capability of 250 metric tons per 12 months (TPY). The forthcoming industrial facility in Holyoke shall be able to producing as much as 30,000 TPY of Elegant Cement™. It’s slated to open as early as 2026, boasting vital reductions in fossil gasoline air pollution usually related to industrial progress.

Elegant Techniques’ method hinges on two main improvements: electrochemical reactions and renewable vitality integration.

As a substitute of conventional strategies that depend on excessive temperatures, Elegant employs electrochemical reactions to provide cement. This revolutionary method eliminates the necessity for burning fossil fuels, thereby considerably lowering carbon emissions.

Then through the use of electrical energy to energy these reactions, Elegant’s crops have the potential to combine renewable energy sources akin to photo voltaic and wind. This strategic shift reduces emissions and aligns with renewable vitality targets, contributing to a extra sustainable future.

Different firms are creating modern methods to seize carbon dioxide to make it as an ingredient in its cement-free, carbon-negative concrete.

Elegant Techniques’ Path to Sustainable Cement Manufacturing

Dr. Leah Ellis, CEO and Co-Founding father of Elegant Techniques highlighted the largest hurdle hindering this type of breakthrough innovation in preventing local weather change, saying:

“Access to sufficient capital for industrial-scale demonstrations is the single biggest obstacle preventing breakthrough innovations from reaching the scale humanity needs to combat the climate crisis.”

Ellis praised the Division of Vitality for addressing this impediment by means of funding from OCED’s Industrial Demonstrations Program (IDP). She expressed pleasure about collaborating with the division on funding their first industrial manufacturing scale-up. It will be capable to produce clear cement whereas fostering financial alternatives for the encircling group.

Moreover, OCED candidates, together with Elegant Techniques, had been mandated by the DOE to submit Neighborhood Advantages Plans (CBPs). These plans define methods to interact communities, create high-quality jobs, and prioritize financial and environmental justice for deprived teams.

In Elegant’s case, their determination to determine their first industrial manufacturing facility in Holyoke, Massachusetts was guided by screening instruments developed by Justice 40. The startup anticipates the creation of a whole bunch of jobs through the building part of the mission.

The corporate has solid a strategic partnership settlement with the United Steelworkers (USW), representing roughly half of unionized cement employees within the U.S., specializing in operational roles within the Holyoke plant. Moreover, Elegant has entered right into a Memoranda of Understanding to barter mission labor agreements with constructing commerce unions within the area for the development part.

Elegant Techniques’ Holistic Strategy

Augmenting Elegant’s Neighborhood Advantages Plan is a collaboration with the Smithsonian Science Training Middle (SSEC). The OCED choice contains funding to leverage SSEC’s academic programming sources to assist this goal.

U.S. Secretary of Vitality Jennifer M. Granholm emphasised the essential function of advancing decarbonization technologies in pivotal industries akin to metal, paper, concrete, and glass. She underscored the importance of President Biden’s industrial technique, facilitating the Division of Vitality’s (DOE) historic funding in industrial decarbonization.

Granholm highlighted the goal to considerably cut back emissions from hard-to-decarbonize sectors, making certain that American companies and employees stay aggressive on the worldwide stage.

Elegant has already secured reservations for over 45,000 tons of Elegant Cement™, demonstrating robust demand for his or her sustainable cement.