Graphical summary. Credit score: Chemical Engineering Journal (2024). DOI: 10.1016/j.cej.2024.149881

Professor Hongkyung Lee of DGIST’s Vitality Science and Engineering collaborated with Dr. Chanhoon Kim’s Clear Vitality Conversion Group on the Korea Institute of Industrial Expertise (KITECH) to introduce a stabilization expertise for unstable battery techniques by way of the adoption of a dual-layer coating methodology. The work is published within the Chemical Engineering Journal.

Lithium steel, famend as a super anode materials for batteries, has a theoretical capability ten occasions larger than commercially used graphite, thereby permitting the creation of batteries surpassing power density limits of present secondary lithium batteries. Nonetheless, lithium-ion batteries pose fireplace and explosion dangers throughout overcharging or over-discharge, thus creating vital constraints for his or her use in electric vehicles and transportable digital units. Consequently, analysis on secure different applied sciences is being actively pursued.

Aqueous zinc batteries, recognized for his or her high energy density and environmentally pleasant traits, are drawing vital consideration within the power storage system (ESS) sector. Considered a secure different expertise, efforts to reinforce their activation are deemed essential. Nonetheless, the commercialization of aqueous zinc batteries has but to be achieved because of challenges similar to zinc dendrite formation, hydrogen evolution reactions, and zinc corrosion.

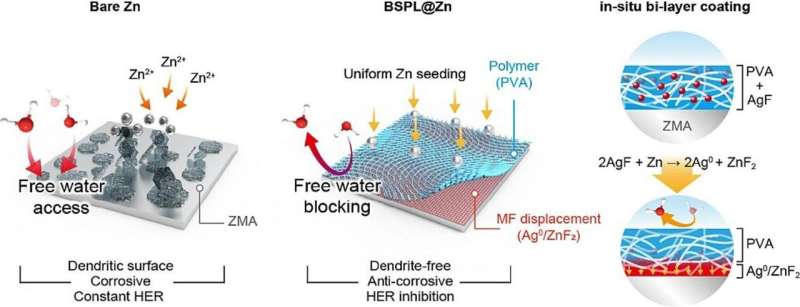

To handle these points, Professor Lee’s staff launched a novel dual-layer coating method using each polymers and inorganic supplies. This course of entails concurrently making use of steel fluoride and polymer resolution onto zinc steel. The steel fluoride is positioned within the decrease layer, whereas the non-reactive polymer layer is positioned above.

The higher polymer layer successfully prevents direct contact between water and zinc steel, thereby suppressing hydrogen evolution reactions by over threefold and stopping zinc steel corrosion. In the meantime, the steel fluoride layer beneath reveals zincophilic properties, successfully inhibiting zinc dendrite formation.

Professor Hongkyung Lee from the Division of Vitality Science and Engineering acknowledged, “This research has innovatively addressed the persistent challenges of aqueous zinc batteries, including zinc dendrites, hydrogen evolution reactionsand zinc corrosion, through a simple dual-layer design. We anticipate that this technology will expand to various systems utilizing metal anodes, beyond just zinc.”

Extra info:

Jaewoong Han et al, In-situ coating of steel fluoride/polymer bi-layer safety for dendrite-free, anti-corrosive Zn-metal anode, Chemical Engineering Journal (2024). DOI: 10.1016/j.cej.2024.149881

Supplied by

DGIST (Daegu Gyeongbuk Institute of Science and Expertise)

Quotation:

Accelerating the sensible software of next-gen batteries which can be fire-resistant by way of dual-layer coating (2024, Could 8)

retrieved 9 Could 2024

from https://techxplore.com/information/2024-05-application-gen-batteries-resistant-dual.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for info functions solely.