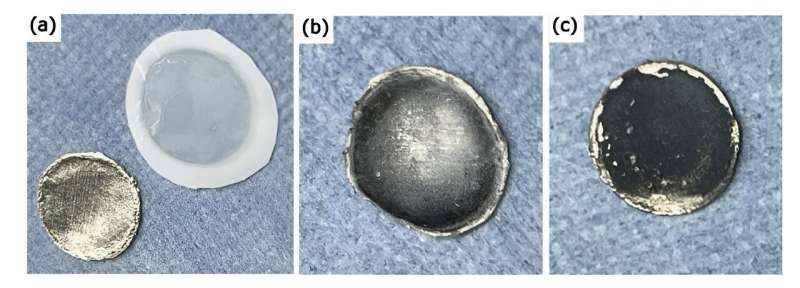

Optical pictures of lithium below three situations: a) lithium foil with no FG coating (with electrolyte), b) FG pressed on Li foil with out electrolyte, c) SEI fashioned after 2 days relaxation in FG@CM cell (with electrolyte). Credit score: Small (2023). DOI: 10.1002/smll.202308344

Lithium steel batteries (LMBs) can present almost 10 occasions increased power density in comparison with the current Lithium-ion batteries (LIBs) and therefore are recognized as one of many potential future storage methods. Nevertheless, LMBs pose sure security issues and can’t be used for fast-charging purposes. Uncontrolled dendrite formation, resulting in extreme heating and battery brief circuit is without doubt one of the vital challenges of its development.

Researchers have beforehand tried to handle the security issues in LMBs, however with strategies that had been laborsome and cash/time- intensive. Now T. N. Narayanan’s lab on the Tata Institute of Elementary Analysis, Hyderabad (TIFRH) reviews a easy, scalable, cost-effective methodology to assemble a safer and sturdy lithium steel battery.

The analysis is published within the journal Small.

A porous separator membrane lies between the electrodes in a battery, conserving them aside, and is essential to forestall a short circuit. When a battery is used for a while, tree-like buildings or whiskers known as dendrites start to type on one of many electrodes. If these dendrites develop uncontrollably, they could in some sense develop into a bodily bridge between the 2 electrodes inflicting a brief circuit.

Preeti Yadav and Pallavi Thakur, graduate college students and lead authors of the research, used a generally obtainable graphite spinoff powder to switch the separator membrane utilized in a typical battery. This modification suppresses dendrite formation and improves the longevity of the battery to a big extent. The researchers suggest that this methodology of separator modification holds immense potential to be scaled up for industrial utilization.

Nevertheless, at a really excessive present density of 10 mA cm-2the battery appears to be deteriorating slowly. This might be due to the electroplating of lithium on the carbon (a element of the deposited graphite spinoff layer). The researchers intention to analyze these challenges additional and perceive the function of interfaces in bettering the efficiency of a battery from a basic standpoint.

Extra info:

Preeti Yadav et al, Excessive Fee, Dendrite Free Lithium Metallic Batteries of Prolonged Cyclability by way of a Scalable Separator Modification Strategy, Small (2023). DOI: 10.1002/smll.202308344

Supplied by

Tata Institute of Fundamental Research

Quotation:

New research reviews scalable and cost-effective methodology to assemble a safer and sturdy lithium steel battery (2024, March 20)

retrieved 21 March 2024

from https://techxplore.com/information/2024-03-scalable-effective-method-safer-durable.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for info functions solely.