A compact, light-weight sensor system with infrared imaging capabilities might be simply fitted to a drone for distant crop monitoring, in keeping with the group behind it.

The flat-optics know-how is claimed to have the potential to switch conventional optical lens functions for environmental sensing in a spread of industries. One outcome might be cheaper groceries as farmers would have the ability to pinpoint which crops require irrigation, fertilisation and pest management, as an alternative of taking a one-size-fits-all strategy, thereby doubtlessly boosting their harvests.

The sensor system can quickly change between edge detection – imaging the define of an object, equivalent to a fruit – and extracting detailed infrared info, with out the necessity for creating giant volumes of information and utilizing cumbersome exterior processors.

The aptitude to modify to an in depth infrared picture is a brand new growth within the area and will enable farmers to gather extra info when the distant sensor identifies areas of potential pest infestations.

Printed in Nature Communicationsthe analysis was carried out by engineers on the Metropolis College of New York (CUNY), the College of Melbourne, RMIT College and the ARC Centre of Excellence for Transformative Meta-Optical Programs (TMOS).

How does the sensor system work?

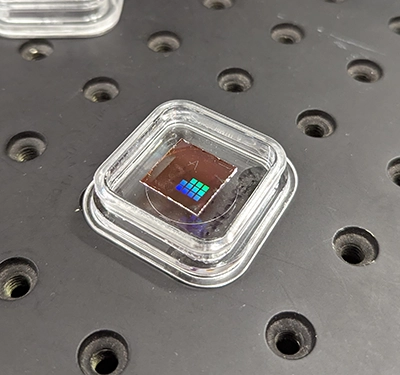

The prototype sensor system includes a filter made with a skinny layer of vanadium dioxide that may change between edge detection and detailed infrared imaging. It was engineered by TMOS Chief Investigator Professor Madhu Bhaskaran and her staff at RMIT in Melbourne.

“Materials such as vanadium dioxide add a fantastic tuning capability to render devices ‘smart’”, she stated.

“When the temperature of the filter is changed, the vanadium dioxide transforms from an insulating state to a metallic one, which is how the processed image shifts from a filtered outline to an unfiltered infrared image.”

“These supplies might go a good distance in futuristic flat-optics gadgets that may exchange applied sciences with conventional lenses for environmental sensing functions – making them splendid to be used in drones and satellites, which require low measurement, weight and energy capability.

RMIT holds a granted US patent and has a pending Australian patent utility for its methodology of manufacturing vanadium dioxide movies, which can be appropriate for a broad vary of functions.

Lead writer Dr Michele Cotrufo stated the system’s means to modify between processing operations, from edge detection to capturing detailed infrared photographs, was important.

“While a few recent demonstrations have achieved analogue edge detection using metasurfaces, most of the devices demonstrated so far are static. Their functionality is fixed in time and cannot be dynamically altered or controlled,” stated Corufo, who carried out his analysis at CUNY.

“Yet, the ability to dynamically reconfigure processing operations is key for metasurfaces to be able to compete with digital image processing systems. This is what we have developed.”

Subsequent steps

Co-author Shaban Sulejman from the College of Melbourne stated the design and supplies used make the filter amenable to mass-manufacturing.

“It also operates at temperatures compatible with standard manufacturing techniques, making it well-placed to integrate with commercially available systems and therefore move from research to real-world usage rapidly.”

TMOS Chief Investigator Ann Roberts, additionally from the College of Melbourne, stated flat optics applied sciences had the potential to rework numerous industries.

“Traditional optical elements have long been the bottleneck preventing the further miniaturisation of devices. The ability to replace or complement traditional optical elements with thin-film optics breaks through that bottleneck.”

‘Reconfigurable image processing metasurfaces with phase-change materials’ is revealed in Nature Communications (DOI: 10.1038/s41467-024-48783-3).