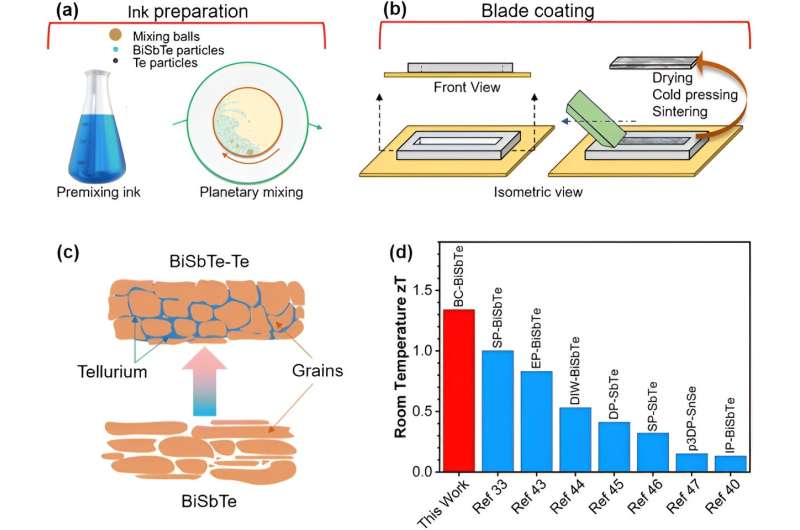

(a) Schematic illustration of the thermoelectric ink formulation. (b) Blade coating for fabricating thick thermoelectric movies. (c) Schematic of the Te-assisted liquid-phase sintering of BiSbTe. (d) Comparability of room-temperature zT between our blade-coated BiSbTe–Te pattern and different p-type thermoelectric supplies made with totally different ink-based processes. Credit score: Vitality & Environmental Science (2024). DOI: 10.1039/D4EE00866A

Energy crops, factories, automobile engines—every thing that consumes power produces warmth, a lot of which is wasted. Thermoelectric units may seize this wasted warmth and convert it into electrical energy, however their manufacturing has been prohibitively pricey and complicated.

Yanliang Zhang, the Superior Supplies and Manufacturing Collegiate Professor of Aerospace and Mechanical Engineering on the College of Notre Dame, and colleagues from a multi-institutional crew have devised an ink-based manufacturing technique making possible the large-scale and cost-effective manufacturing of extremely environment friendly thermoelectric units.

Their discovering had been lately published in Vitality & Environmental Science.

“Using our novel ink recipe and processing technique, we’ve been able to produce a material that’s more efficient in converting waste heat into power than any previous ink-produced device,” Zhang mentioned. “With this method, we can make devices in a broad range of sizes—a film a few microns thick or a device big enough to collect waste heat from a power plant.”

To transform warmth into electrical energy, thermoelectric devices require a scorching facet and a chilly facet. Electrical present ought to move simply via the fabric, however warmth shouldn’t, since that might eradicate the temperature gradient wanted for the gadget to perform effectively.

Supplies with these distinctive properties had been beforehand produced, Zhang mentioned, by labor- and energy-intensive processes that lacked uniformity and scalability.

The crew’s ink “recipe” mixes thermoelectric particles with a solvent plus tellurium, an additive that reduces defects within the materials and helps compact and solidify the ensuing composite. The crew’s ink-based manufacturing method additionally gave them extra management over the fabric’s microstructure and ultimate 3D geometry in contrast with earlier strategies.

Thermoelectric units may also be used for emission- and refrigerant-free cooling, if electrical energy is offered.

“We believe our findings hold great promise for waste heat recovery, energy efficiency improvements, CO2 emission reduction, and environmentally friendly solid-state cooling and refrigeration,” Zhang mentioned.

Extra data:

Ali Newaz Mohammad Tanvir et al, Excessive-performance thermoelectric composites by way of scalable and low-cost ink processing, Vitality & Environmental Science (2024). DOI: 10.1039/D4EE00866A

Supplied by

University of Notre Dame

Quotation:

New ink-based technique gives finest recipe but for thermoelectric units (2024, July 2)

retrieved 2 July 2024

from https://techxplore.com/information/2024-07-ink-based-method-recipe-thermoelectric.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.