What if the world can seize methanea strong greenhouse fuel emitted by industries similar to agriculture and wastewater therapy, and switch it right into a helpful product? That’s precisely what Mango Supplies, a California-based biomanufacturing firm, is innovating.

Mango Materials employs methane-eating microorganisms to remodel methane emissions into polyhydroxyalkanoate (PHA), a biodegradable polymer. This polymer is used to create 100% biodegradable polyester pellets for making sturdy items, materials, and versatile movies.

A Methane-Consuming Micro organism Advances Sustainable Applied sciences

Not like standard plastics, PHA supplies decompose considerably quicker—inside weeks or months. Higher but, they flip again into methane and carbon dioxide when disposed of correctly.

Allison Pieja, Mango’s co-founder and Chief Expertise Officer, emphasizes the huge advantages of their expertise, saying:

“Our analyses show it should be carbon negative when running at full scale.”

Mango just lately accomplished a PHA manufacturing facility at a wastewater therapy plant in Vacaville, California. Right here, they capture methane from microbes that clear the general public water provide and channel it into bioreactors with their methane-consuming micro organism.

The micro organism convert methane into chains of PHA to retailer power, akin to how crops retailer power in starches by linking carbon dioxide-based sugars. These PHA molecules accumulate contained in the bacterial cells for later use.

The corporate is already producing sufficient PHA for demonstration merchandise, together with a cleaning soap dish on the market, internet zero sneakers by Allbirds, and sustainable sun shades designed by Stella McCartney.

Mango Supplies goals to scale up manufacturing to provide PHA pellets for a broad vary of eco-friendly merchandise. CEO and co-founder Molly Morse mentioned that there’s an enormous market alternative for bio-based plastics with the identical biodegradability profile as PHA mixed with its mechanical properties.

Collaborating for Scale Up

Transitioning from lab-scale analysis to a industrial course of took time. The Superior Biofuels and Bioproducts Course of Growth Unit (ABPDU) at Lawrence Berkeley Nationwide Laboratory performed an important position.

Funded by the U.S. Division of Power’s Bioenergy Applied sciences Workplace, ABPDU makes a speciality of scaling up bio-based technologies. Mango’s group, based in 2012, labored with ABPDU to optimize their bacterial tradition and the situations for prime PHA yields.

ABPDU, led by Ning Solar, examined industrial-scale gear with Mango scientists to refine the extraction of PHA from microbial broth. Solar famous that they’ve obtained broth from Mango at varied scales and examined completely different restoration unit operations to reinforce yield and purity.

The collaboration resulted in a profitable course of that Mango is assured might be worthwhile. It was essential for the biomanufacturing firm to entry a downstream processing facility and experience.

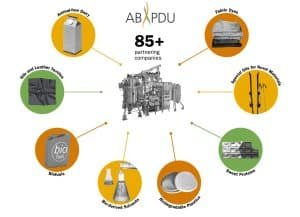

The ABPDU group additionally gained experience in intracellular biopolymer extraction. So far, the ABPDU has assisted 85 trade companions and 20 nationwide laboratories in scaling up progressive biology-based merchandise.

Mango Supplies’ work was supported by Division of Power grants. The ABPDU helps early-stage biofuels, biomaterials, and biochemicals scale from analysis to industrial functions, advancing sustainable applied sciences.

The corporate’s progressive use of micro organism to show methane into biodegradable PHA gives a promising answer to each plastic waste and greenhouse fuel emissions. Pleasure is excessive when this expertise is scaled for widespread affect.